IoT solutions for tractor-trailer insights

Maximizing performance and safety through vehicle intelligence

Available from

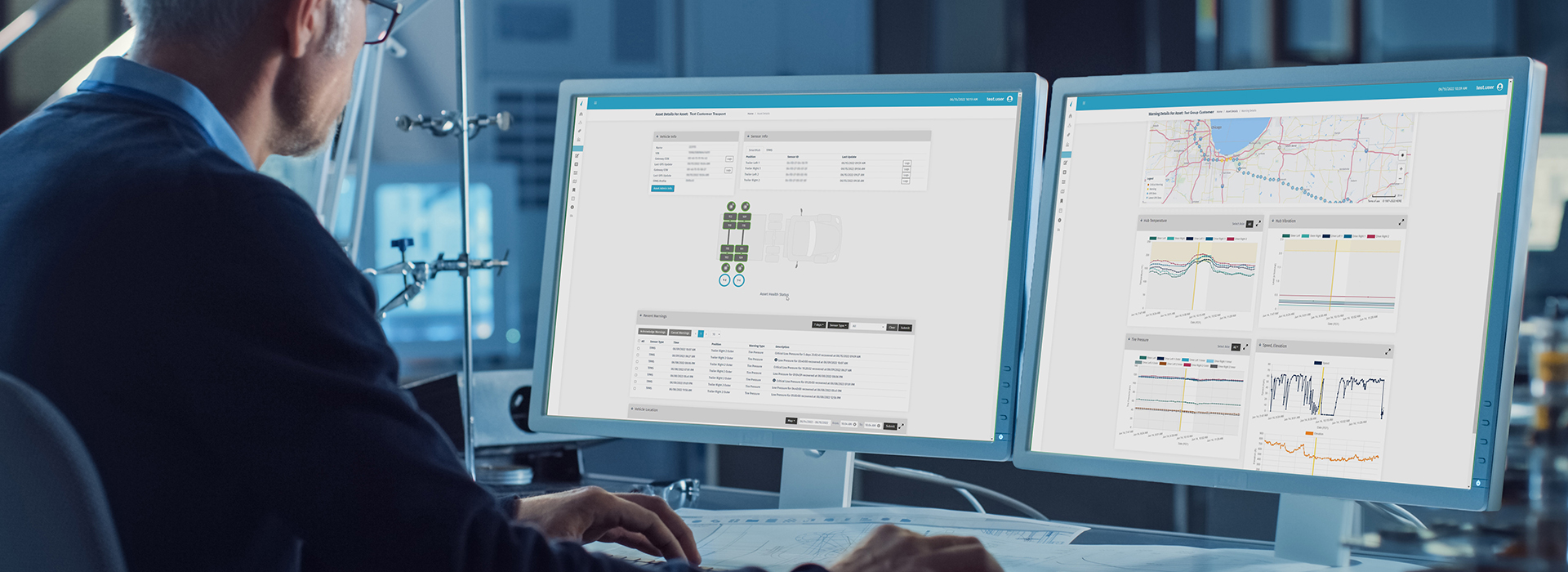

Integrated Data Solutions

At the cutting edge of intelligence and data science, ConMet is driving connected solutions across the commercial vehicle industry.

Our Solutions

A robust set of solutions that leverage today’s cutting edge technology to empower drivers, maintenance managers, and dispatchers to act on critical maintenance needs.

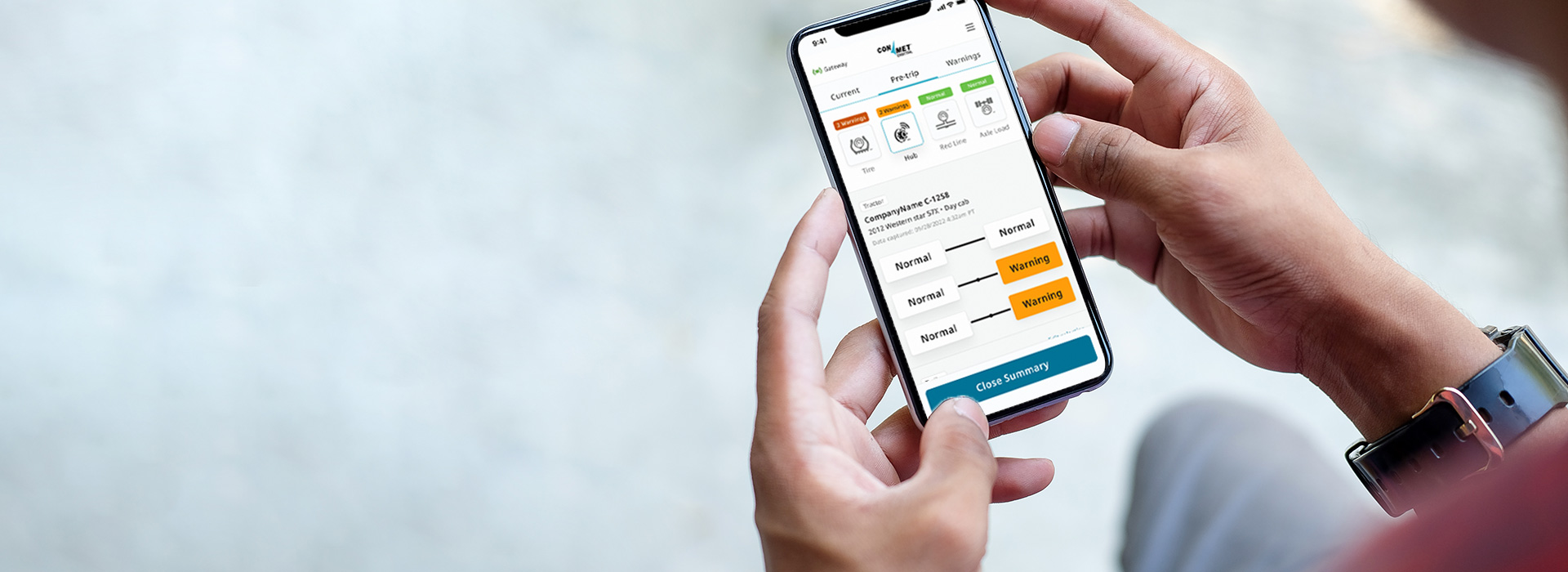

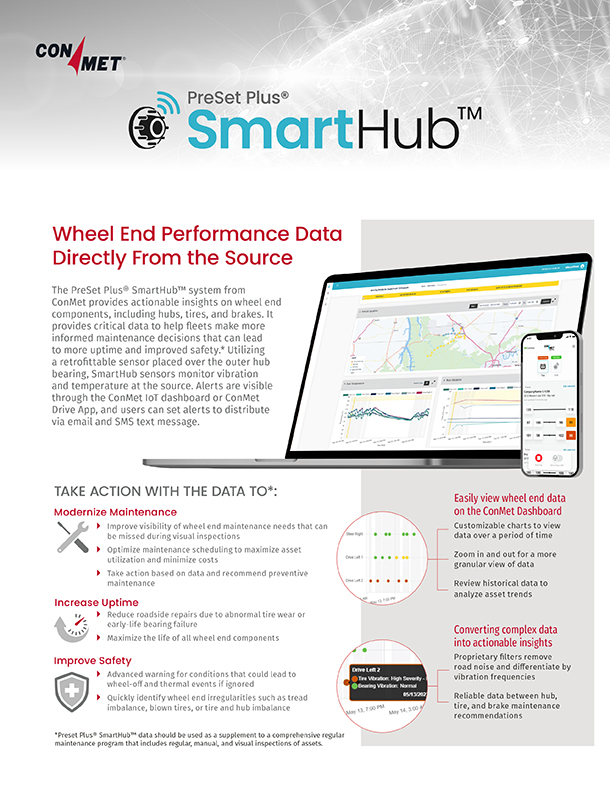

Proprietary algorithms remove road noise and differentiate among common tire and hub issues to create a specific action plan to help fleets make more informed wheel end maintenance decisions.

Advanced warnings for wheel end conditions that could lead to tire blow-outs, wheel-offs, and thermal events if ignored. Quickly identify wheel end irregularities such as tread imbalance, tire tread wear, and tire or hub imbalance.

Improve visibility of wheel end maintenance needs that can be missed during visual inspections. Take action with SmartHub data insights to reduce roadside repairs due to abnormal tire wear or early-life bearing failure.

Optimize maintenance scheduling to maximize asset utilization and minimize costs with SmartHub data insights. An easily retrofittable solution placed over the outer hub bearing that monitors vibration and temperature, at the source, for real-time visibility of wheel end health.

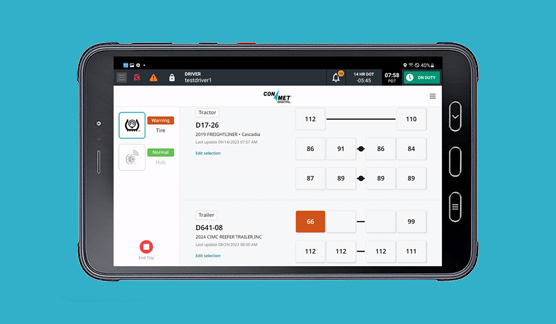

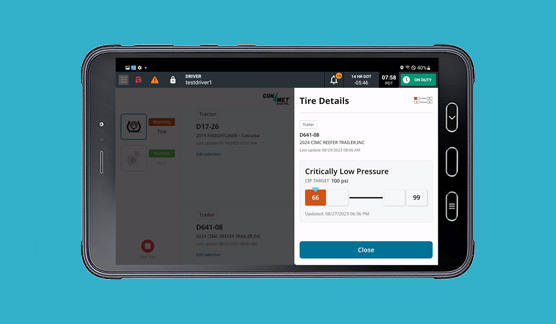

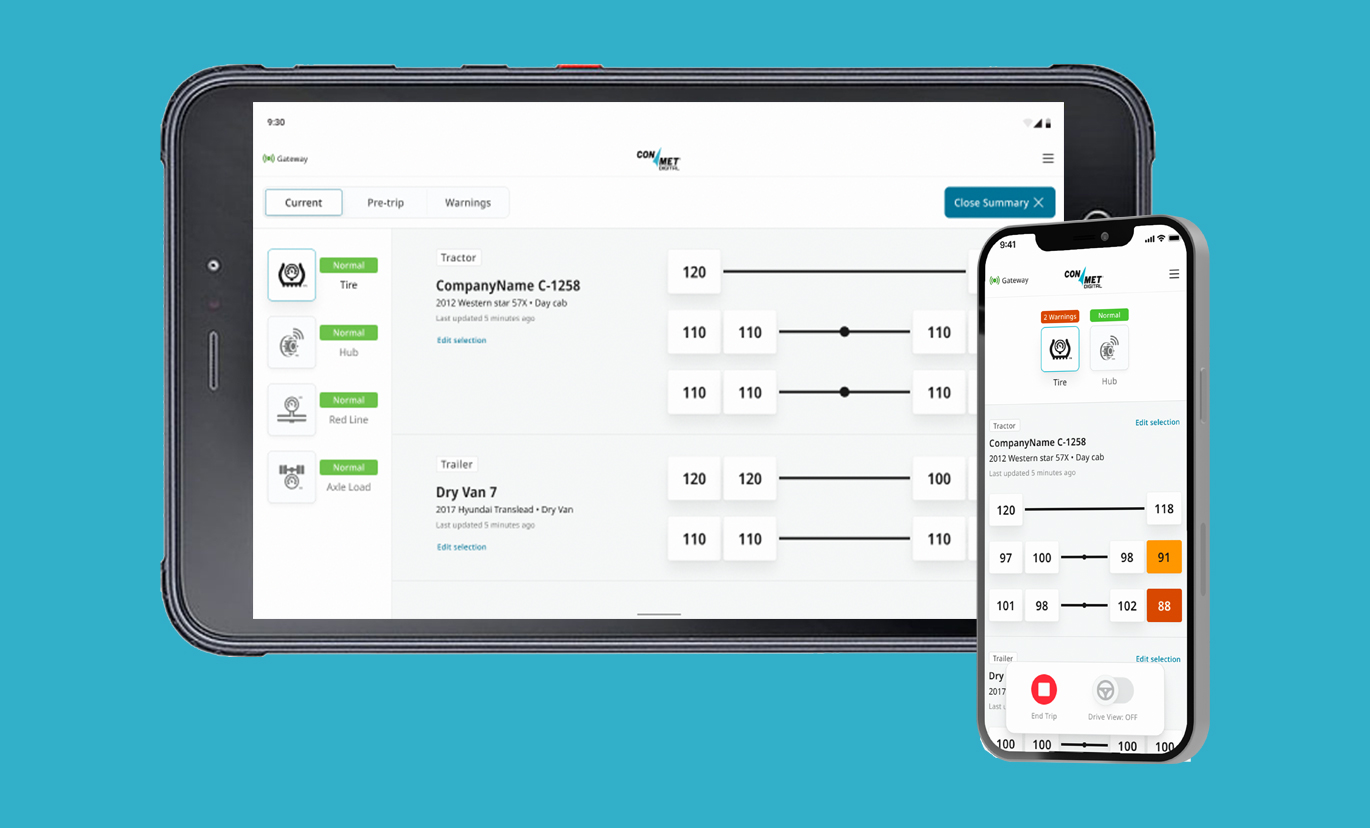

Individual tire pressure measurements every 90 seconds to pinpoint anomalies fast. Allows fleets to take action to maintain preferred tire pressure to optimize fuel efficiency, reduce tire-related roadside repairs, and replacements.

Identify imbalance in tire sets or slow leaks in individual tires so you can take action to extend the life of tires in service.

Gain real-time visibility of asset tire pressure through the ConMet DriverApp and online dashboard. Users can also set alerts for distribution via email and SMS text message.

Set alerts to your preferred fleet PSI thresholds for overinflation and underinflation for each axle, including “Alert” and “Critical Alert” statuses.

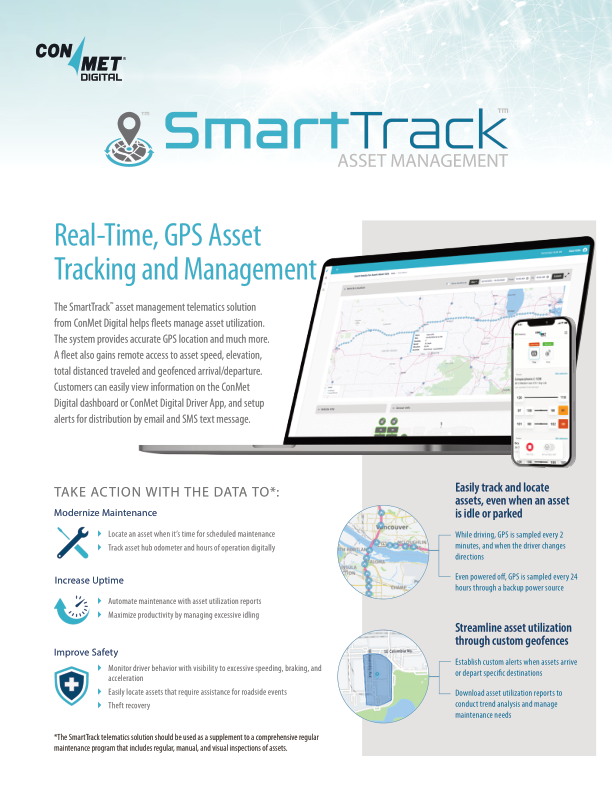

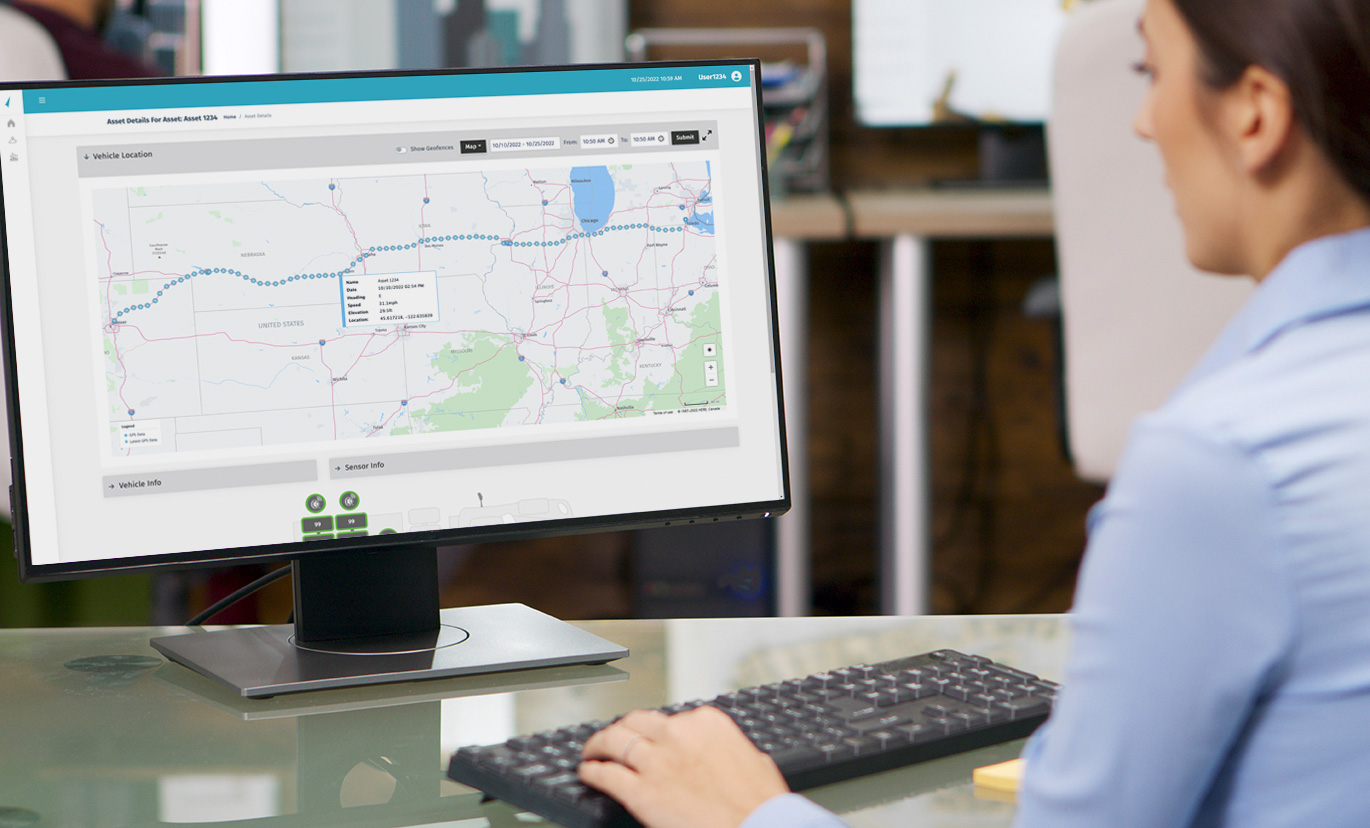

While driving, the asset’s GPS location is sampled every 2 minutes and anytime the asset changes directions.

Even powered off, asset GPS location is sampled every 24 hours through a backup power source that lasts up to nine days disconnected.

Establish custom alerts when assets arrive or depart specific destinations.

Download asset utilization reports to conduct trend analysis and manage maintenance needs.

Connected Solutions In Action

How ConMet’s partners and customers use our products

Featured Literature

Latest News

Newest development, recognition and success stories from ConMet.

Support

Unparalleled Customer Support

At ConMet, we’re your dedicated partner at every turn, offering comprehensive assistance from responsive customer service and hassle-free warranty claims to expert product support and in-depth service training.