eMobility solutions for commercial vehicles

Providing advanced technologies that reduce emissions and enhance performance

Partnered with

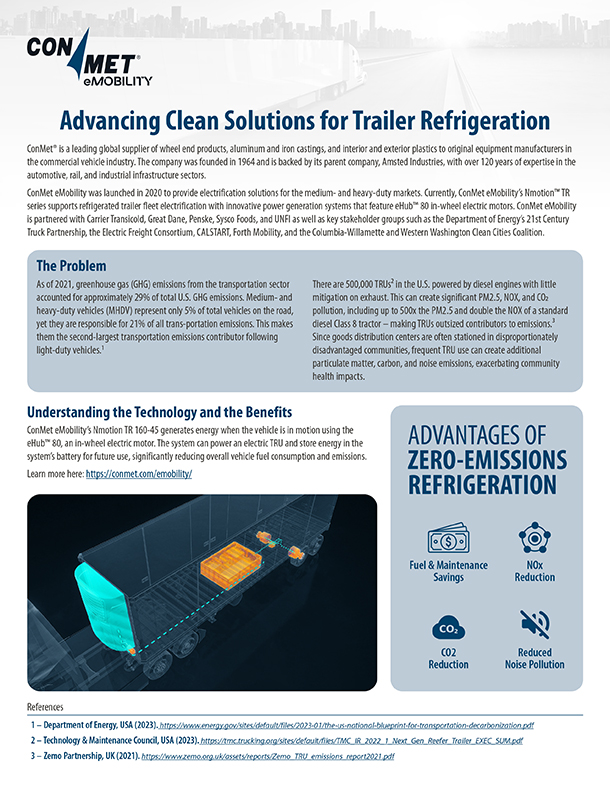

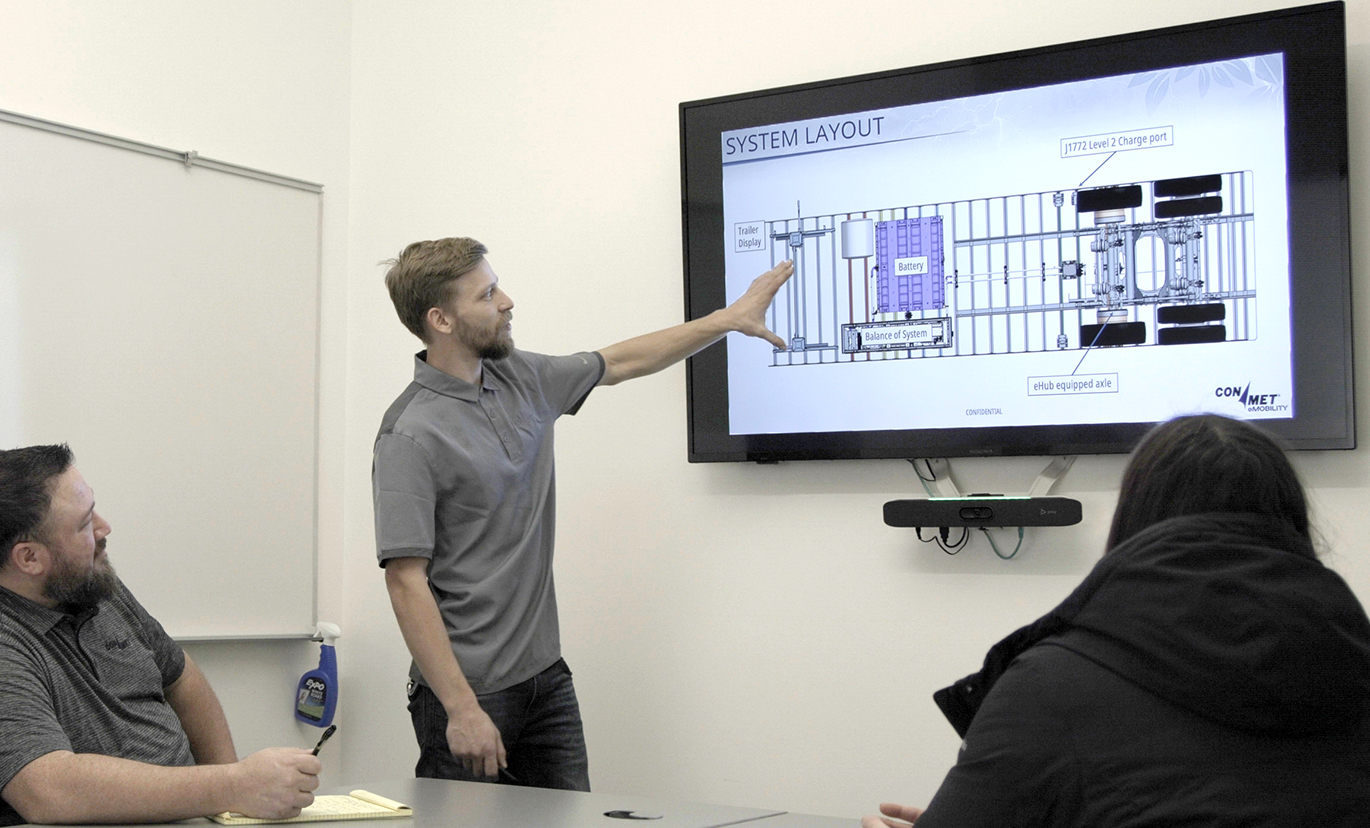

Transformative Technologies for Alternative Power

Building on a 60-year legacy of innovative design, ConMet eMobility is dedicated to providing future-forward alternative power solutions.

Electrification Solutions

ConMet works with customers to develop premium, innovative solutions that drive the commercial vehicle industry toward the future.

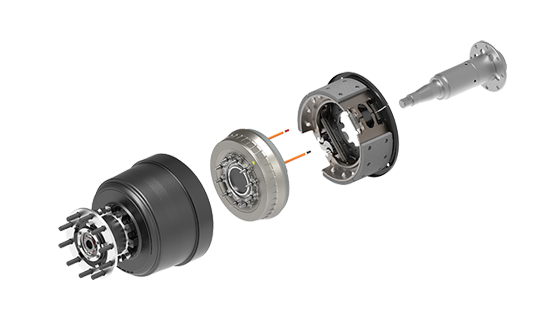

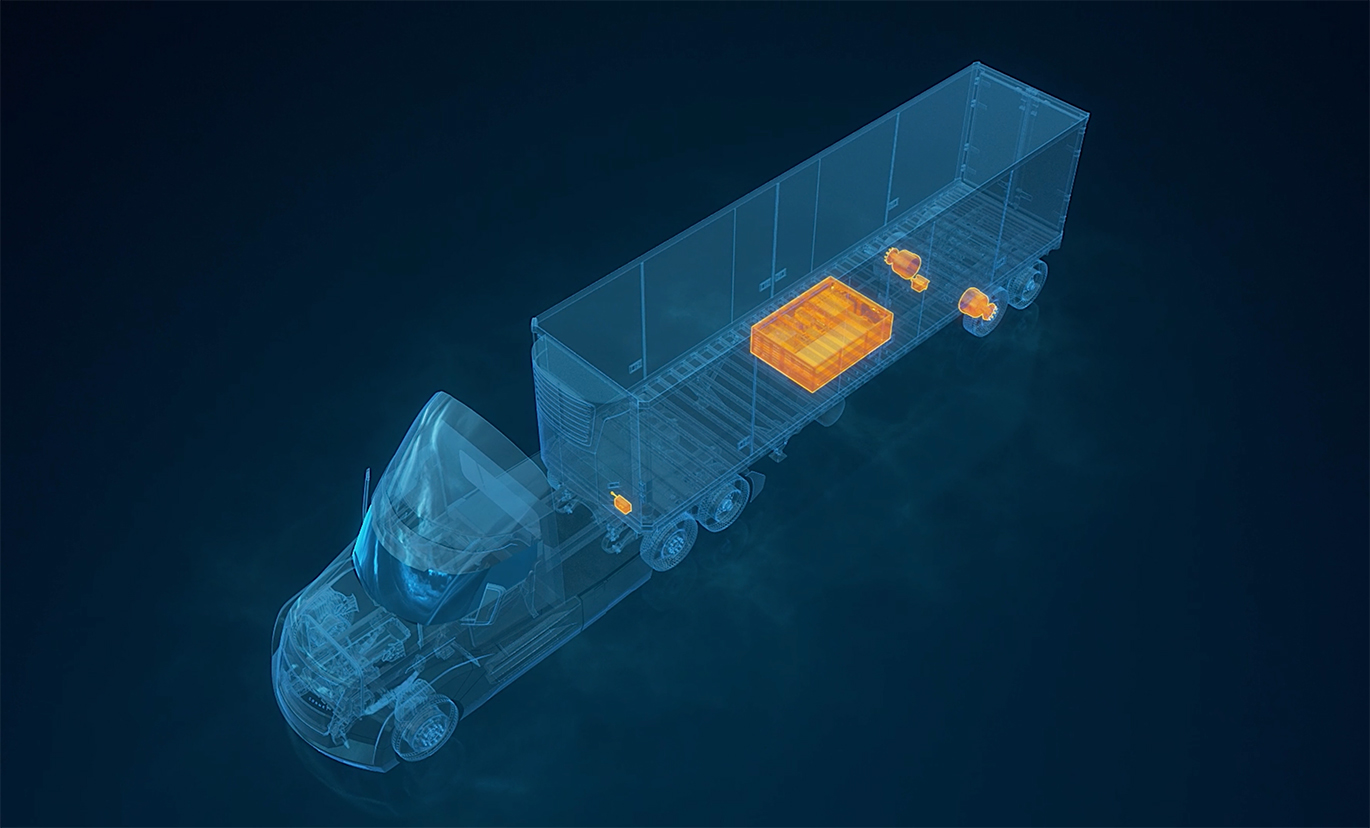

The eHub 80 in-wheel motor generates up to 80kW of power while on the road. The motors’ flexible design is capable of continuous power generation, regenerative braking, and even propulsion assist, depending on the application.

The eHub 80 motors can be powered to help propel a vehicle forward. The propulsion assist mode aids in overall vehicle fuel efficiency or EV range, and allows for quiet vehicle operation.

The eHub 80 motor is positioned behind the PreSet Plus® hub and TruTurn® brake drum. This design allows standard brake and wheel maintenance without touching the motor or electrical wiring.

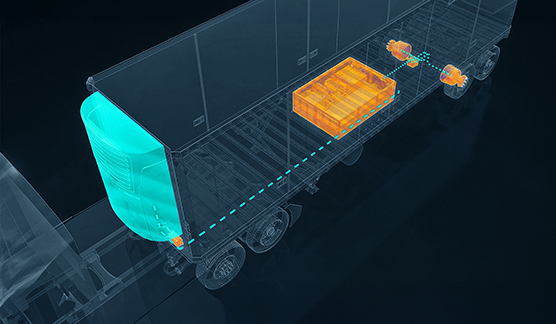

The in-wheel electric motors are controlled by software that manages energy generation or can switch to propulsion assist. The flexibility make many different vehicle applications possible through design integration with OEMs and partners.

With a 10kW peak power generator, the eHub 10 is optimized for most trailer applications.

The outboard-mounted motor of the eHub 10 provides flexibility – it can be used with a standard hubs, standard tires, and standard brake types, including air disc brakes.

The outboard-mounted eHub 10 motor and standard part compatibility accommodate a wide range of trailer lengths, from 28-foot to 53-foot trailers.

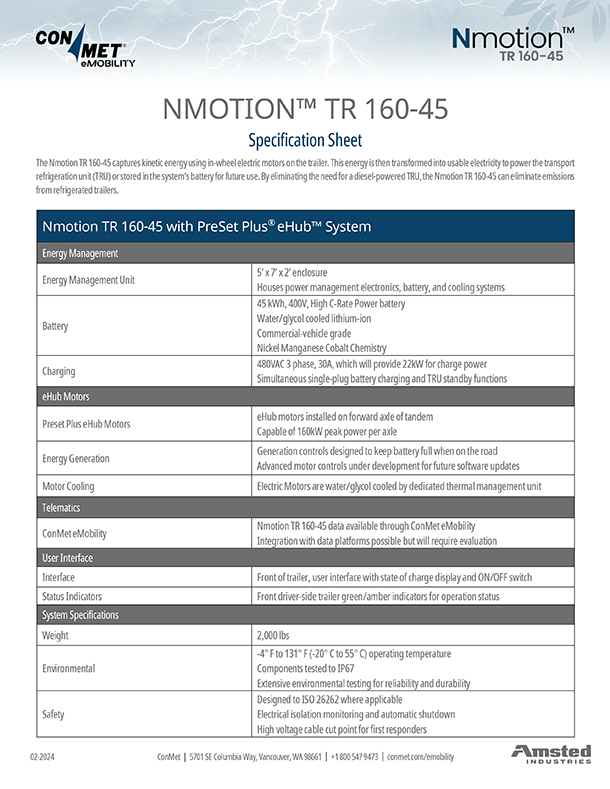

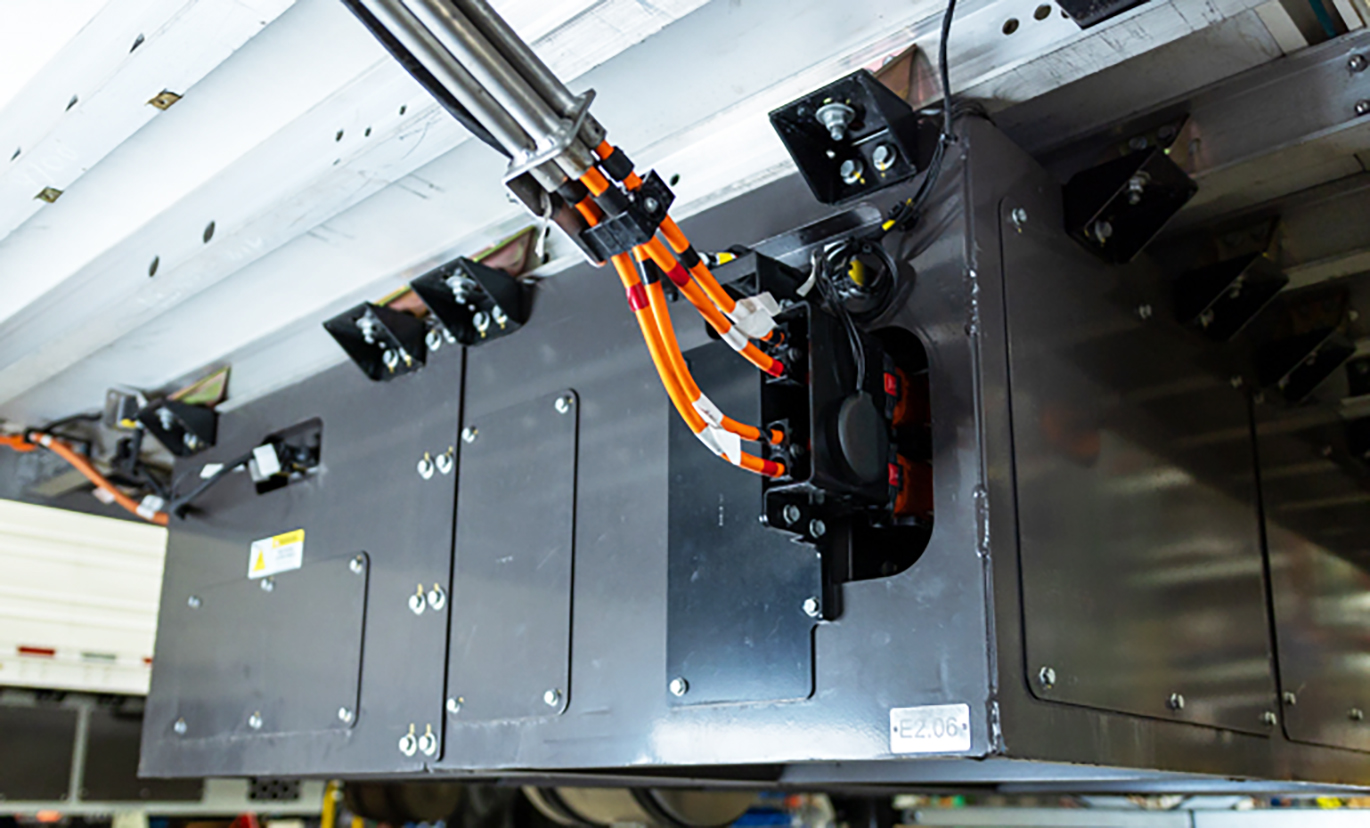

The energy management unit (EMU) includes the high-voltage and low-voltage batteries, battery thermal management, power converter, charger, and the vehicle control unit. The high-voltage battery helps ensure safe and reliable operation and performance over the trailer’s life.

The EMU is compatible with eHub 80 and eHub 10, an integrated vehicle control unit allows the EMU to define how the electrical wheel ends operate. With a single shore power plug, the EMU is capable of simultaneously charging the battery and powering the TRU. The EMU charging port uses 480V three-phase service to send power where it is needed.

Through years of engineering partnerships with most trailer manufacturers, the EMU can be specified as a factory option. This allows for simple, efficient, and streamlined integration.

To keep the system and in-wheel motors operating in extreme weather environments, the EMU has heating and cooling to maintain optimal performance in temperatures ranging from -4° F to 130° F (-20° C to 55° C).

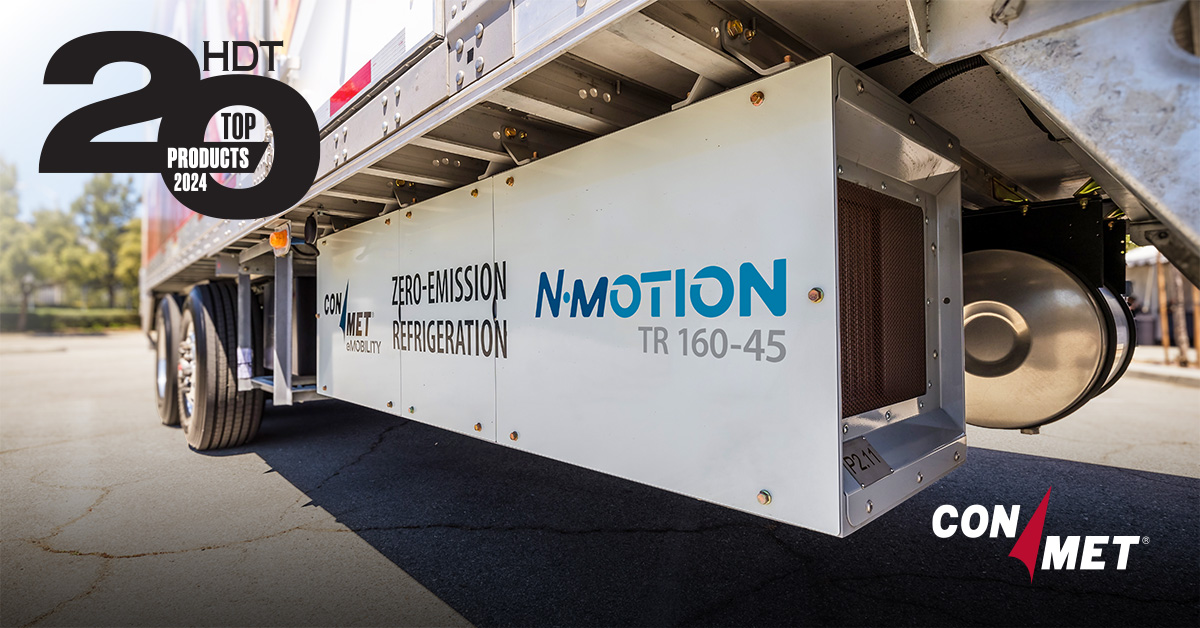

ConMet eMobility in Action

How ConMet eMobility’s partners and customers use our products.

Testimonials

News

Support

Unparalleled Customer Support

At ConMet, we’re your dedicated partner at every turn, offering comprehensive assistance from responsive customer service and hassle-free warranty claims to expert product support and in-depth service training.