Serving the commercial vehicle aftermarket

The most advanced aftermarket wheel end technology

Delivering continued value to the aftermarket

Top quality OEM-approved products backed by best-in-class warranties and support

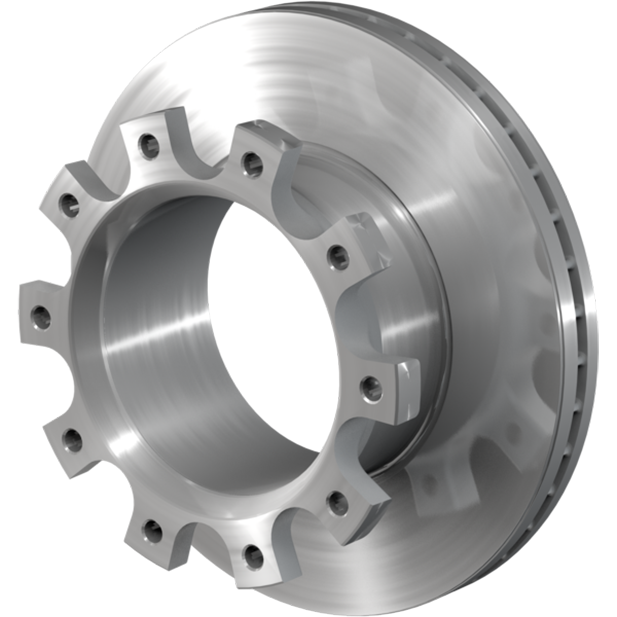

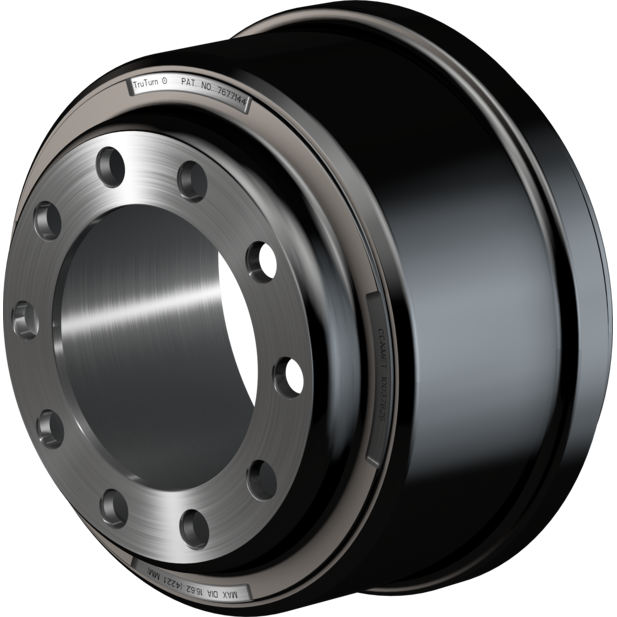

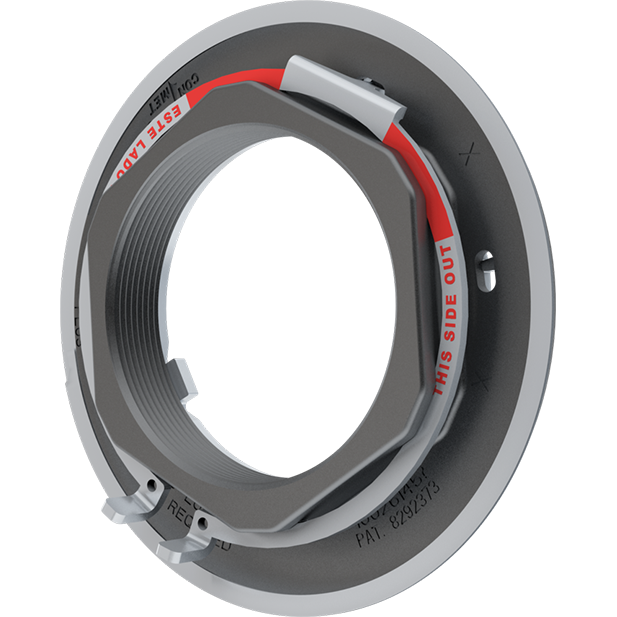

Aftermarket Product Offering

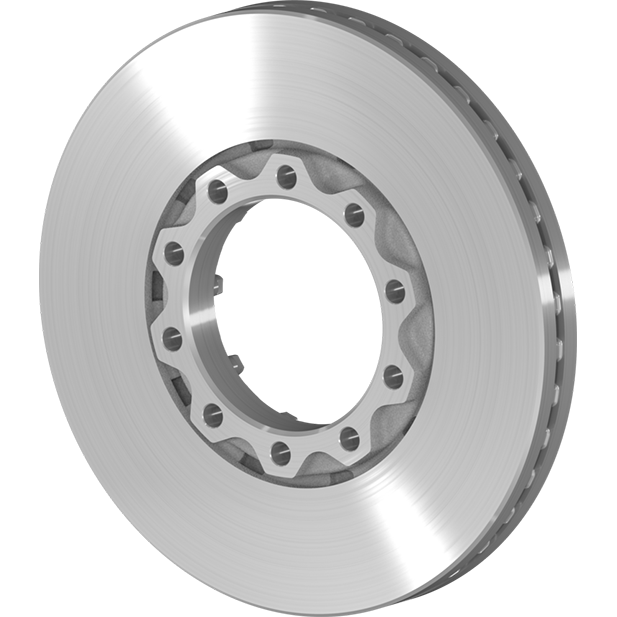

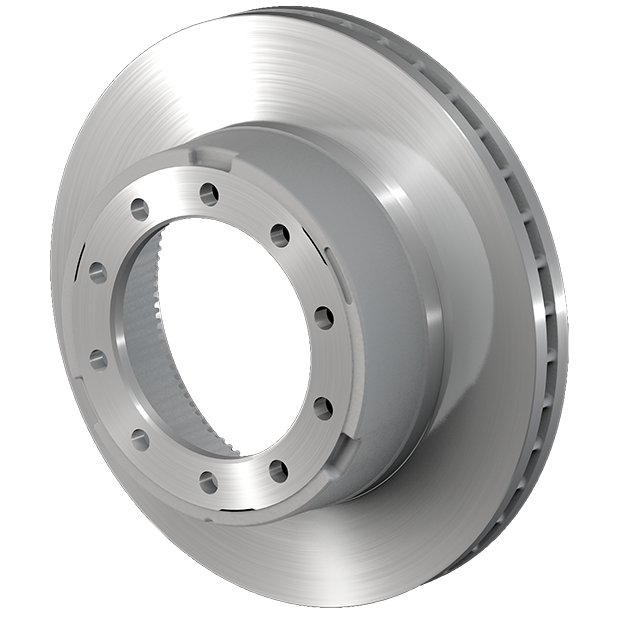

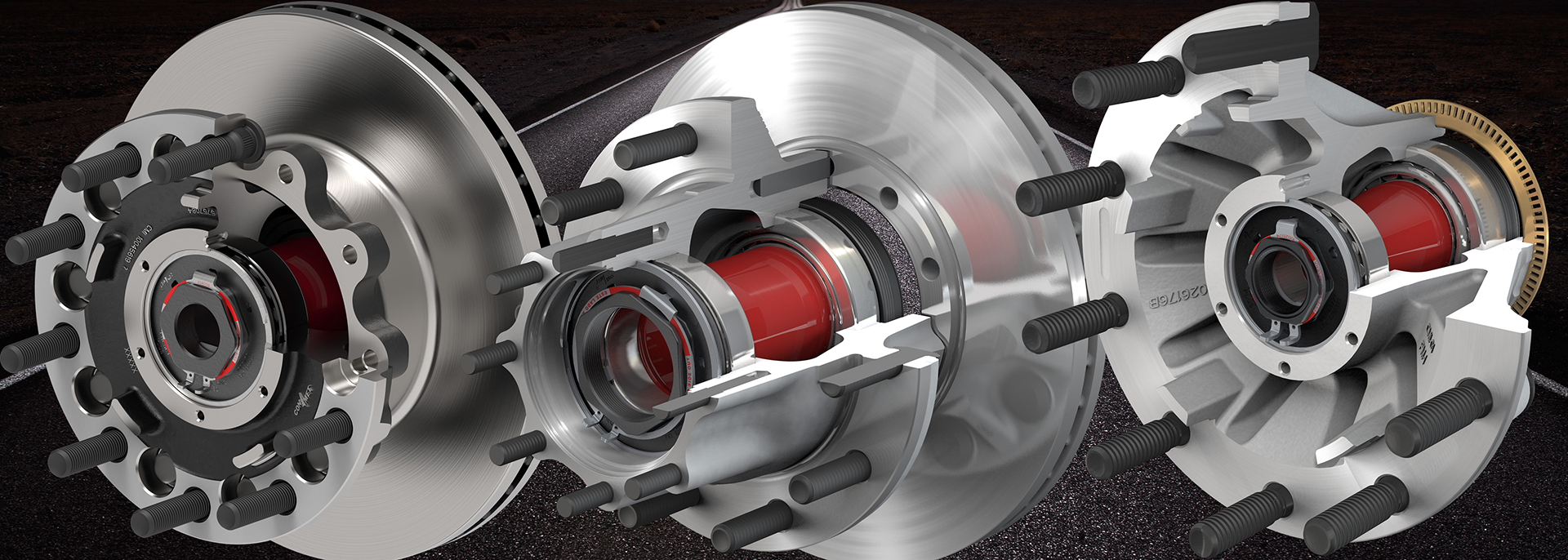

ConMet’s industry-leading commercial wheel end products are available for all axle positions in iron or aluminum.

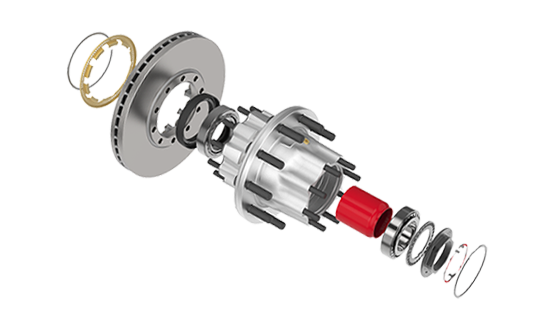

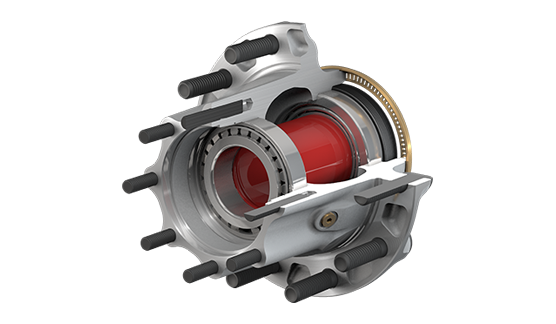

PreSet Plus Hub Assemblies

Our patented PreSet® hub assembly offers benefits no other wheel hub can

Because they’re self-piloting, pre-adjusted and fully assembled, the risk of misalignment or improper installation is greatly reduced. Plus, installation takes a fraction of the time that rebuilding a wheel hub does, resulting in lower labor costs, less downtime, and significant cost savings.

Where to buy

ConMet’s distribution network continues to expand nationwide with leading dealerships, parts supplies and service shops now stocking our products for immediate consumption. We’ve gotten rid of the wait so you can get back on road.

Service Support on the Go

A series of service videos presents a practical solution for technicians seeking to acquire knowledge at their convenience and anywhere. ConMet’s knowledgeable service team offers quick tips and expert advice to ensure that technicians have the information they need to perform maintenance on ConMet hub assemblies with ease.

Get Service Support

Training Platform for Technicians and Sales Staff

Our online training platform provides a convenient way for technicians to learn how to install, remove, and service ConMet PreSet hub assemblies according to their schedule and from anywhere. In addition, sales training videos designed to support the education of counter sales staff are available.

Get Training

Calculate Your Savings

The ConMet app includes two helpful calculators. Use our Rebuild vs. Replace Calculator to see how much time and money you could save by replacing your hub with a PreSet hub instead of rebuilding it. Use our PreSet vs. Conventional Calculator to compare the cost of replacing your hub with a PreSet hub instead of a conventional hub.

Latest News

Paving the Way for Environmental Sustainability

We are dedicated to developing and utilizing sustainable solutions that reduce our carbon footprint, minimize waste, and enhance the world in which we live.

Support

Unparalleled Customer Support

At ConMet, we’re your dedicated partner at every turn, offering comprehensive assistance from responsive customer service and hassle-free warranty claims to expert product support and in-depth service training.