Wheel ends that shaped the industry

We engineer innovative, durable wheel end solutions that deliver unmatched performance

World-Class Wheel Ends

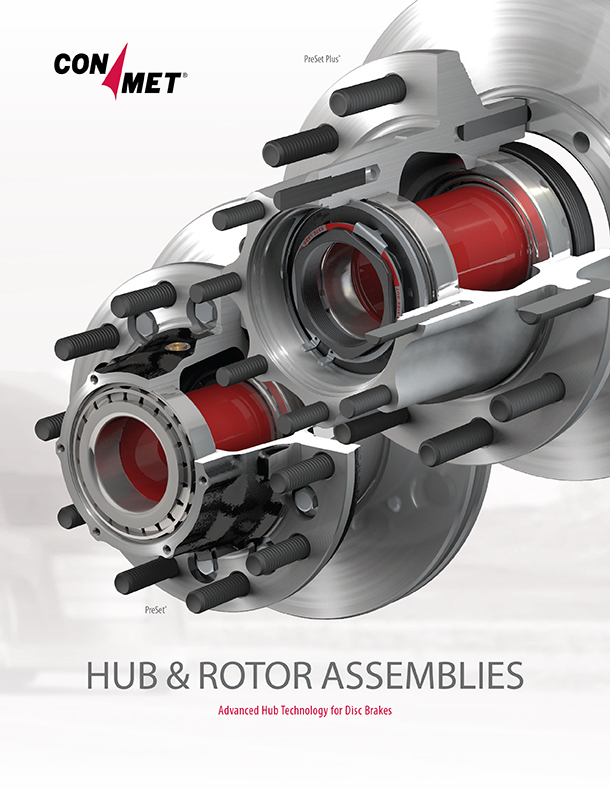

We have defined the industry standard for wheel ends with our PreSet Plus® technology

Designed to set the standard

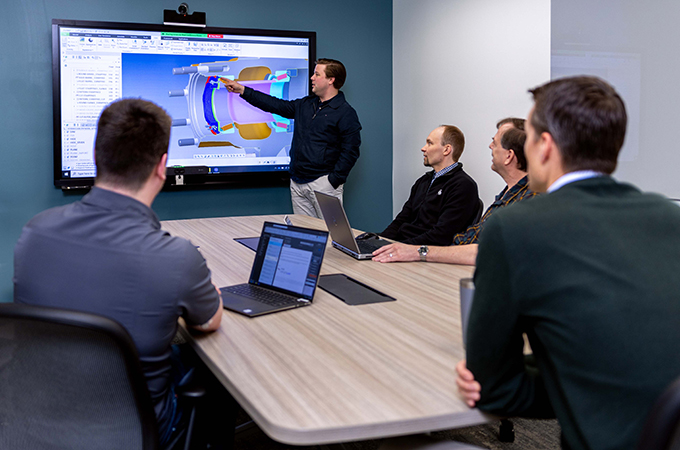

We don’t just manufacture wheel ends. We design, validate, and innovate. We continually set the standard for high performing wheel ends for our customers and the market – always advancing.

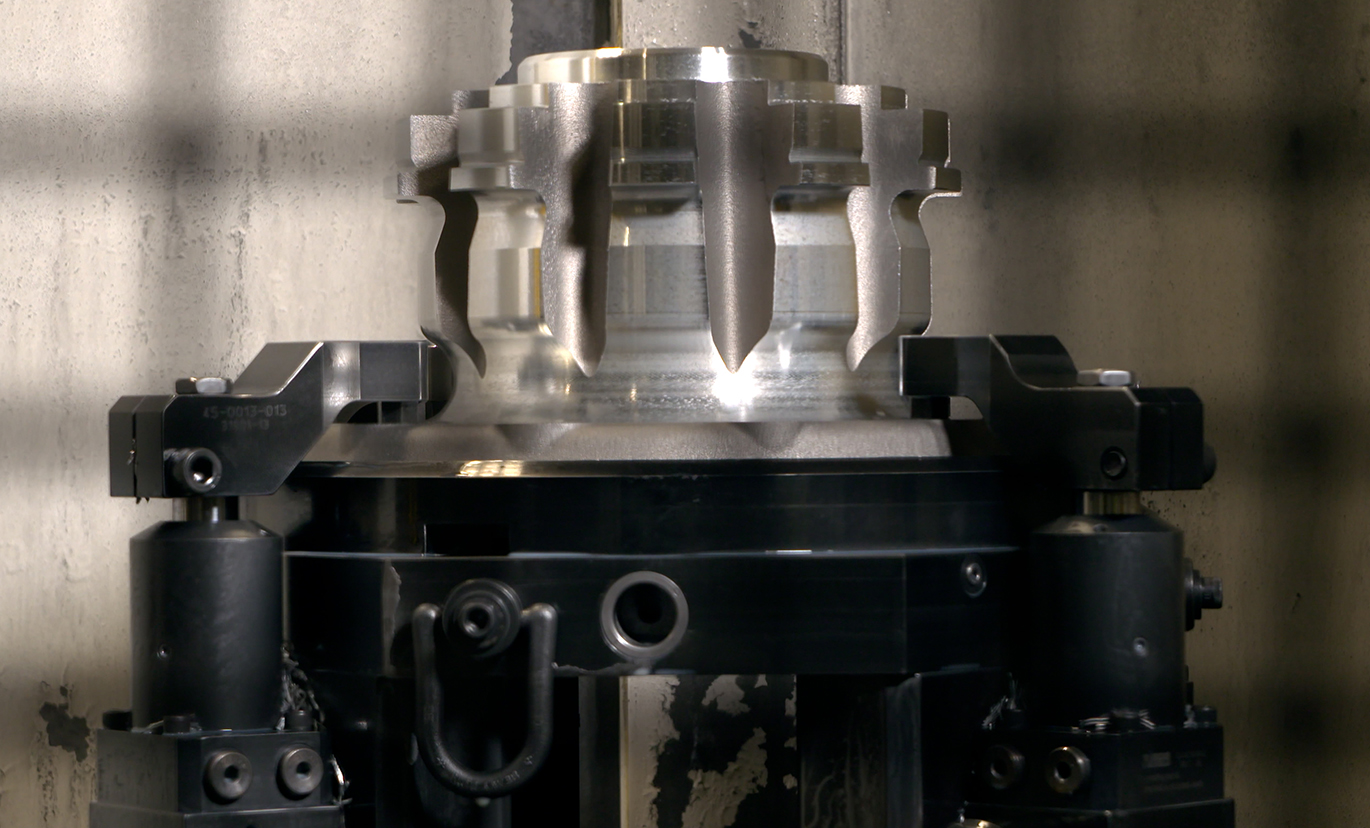

Manufactured to perform

The vertical integration of our materials, processes, testing, and delivery techniques enables us to identify opportunities to improve quality, optimize the supply chain, reduce weight, and drive performance every step of the way.

Ready for the road

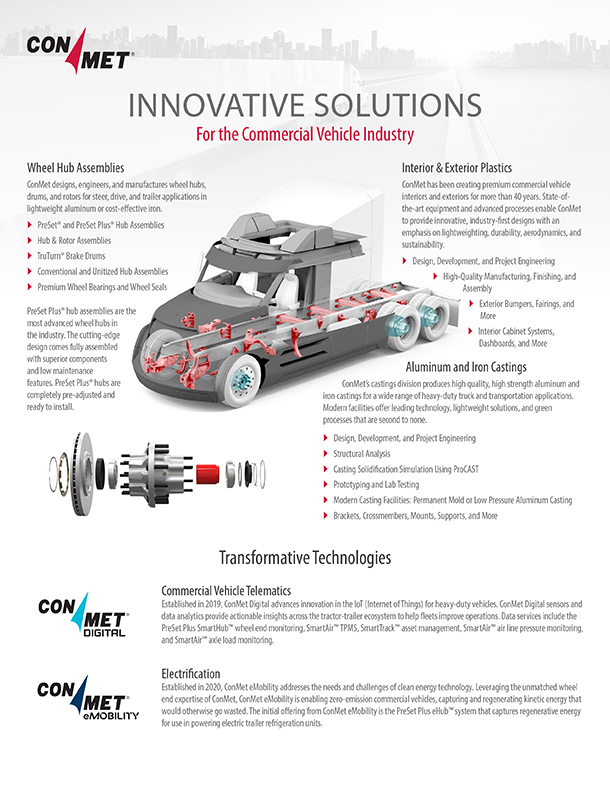

We specialize in lightweight aluminum and offer a full line of aluminum and iron wheel end products. Our proprietary PreSet and PreSet Plus hub technologies last longer, perform better, and are easier to install and maintain. This decreases total cost of ownership while keeping vehicles on the road.

Wheel End Technology

ConMet wheel ends have the full advantage of our 60+ years of design, manufacturing, and validation experience, with the most complete product portfolio in the industry.

ConMet Wheel Ends

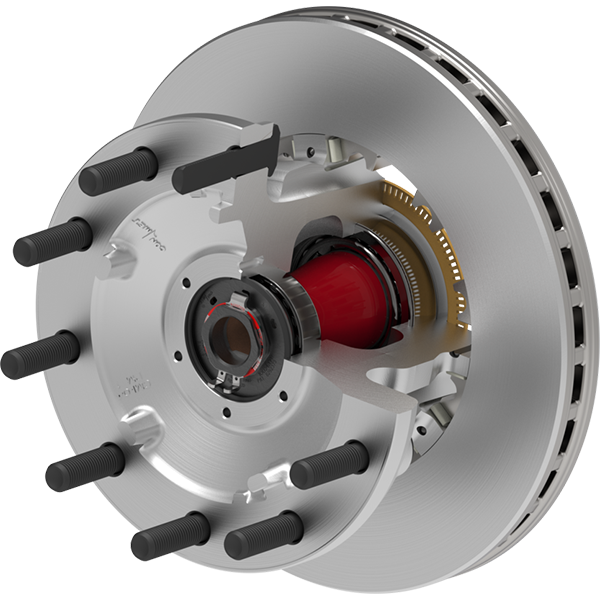

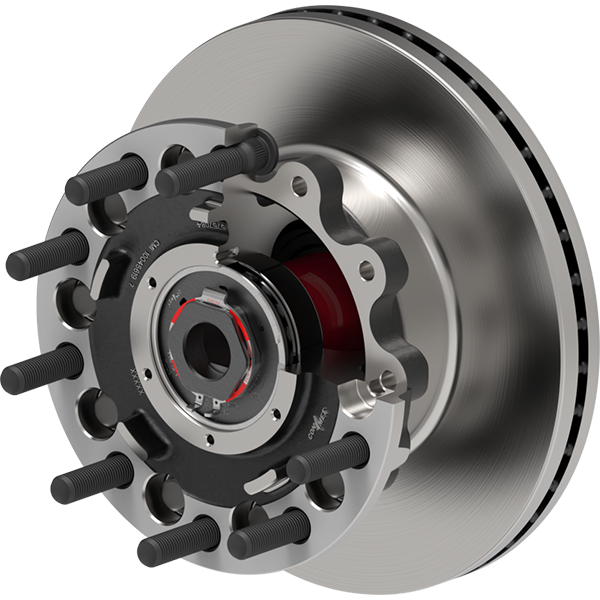

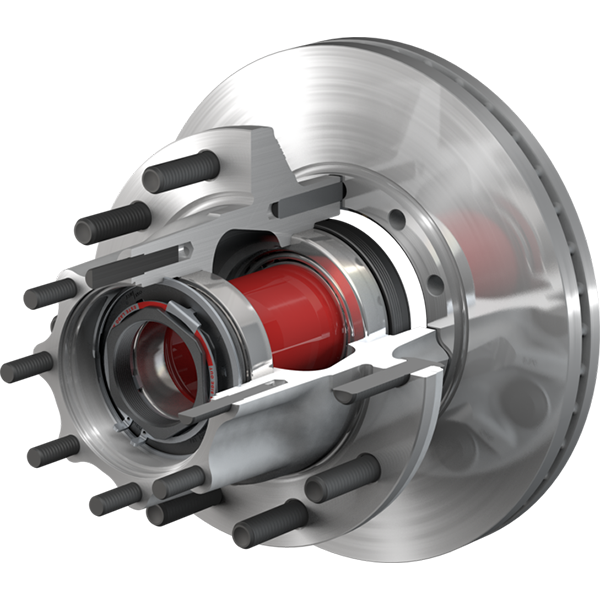

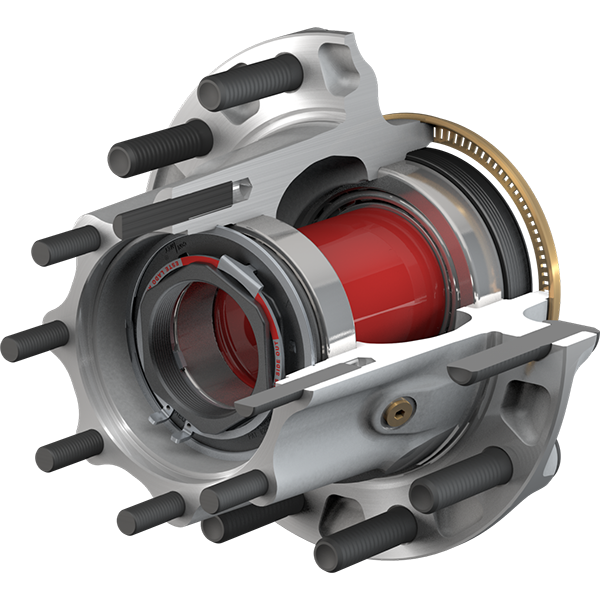

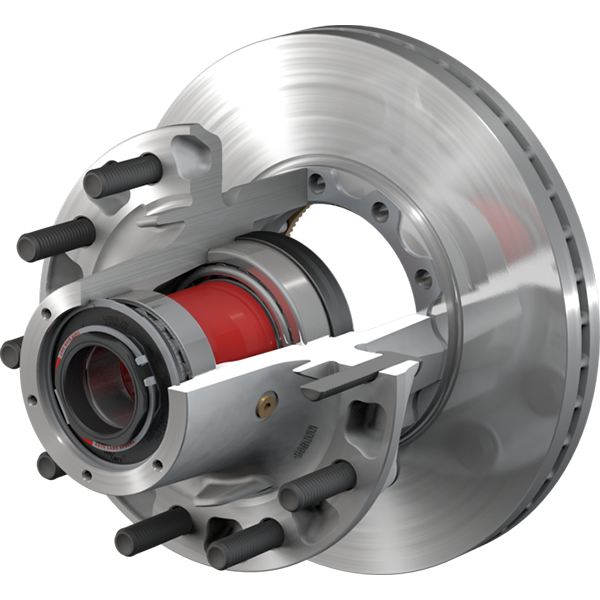

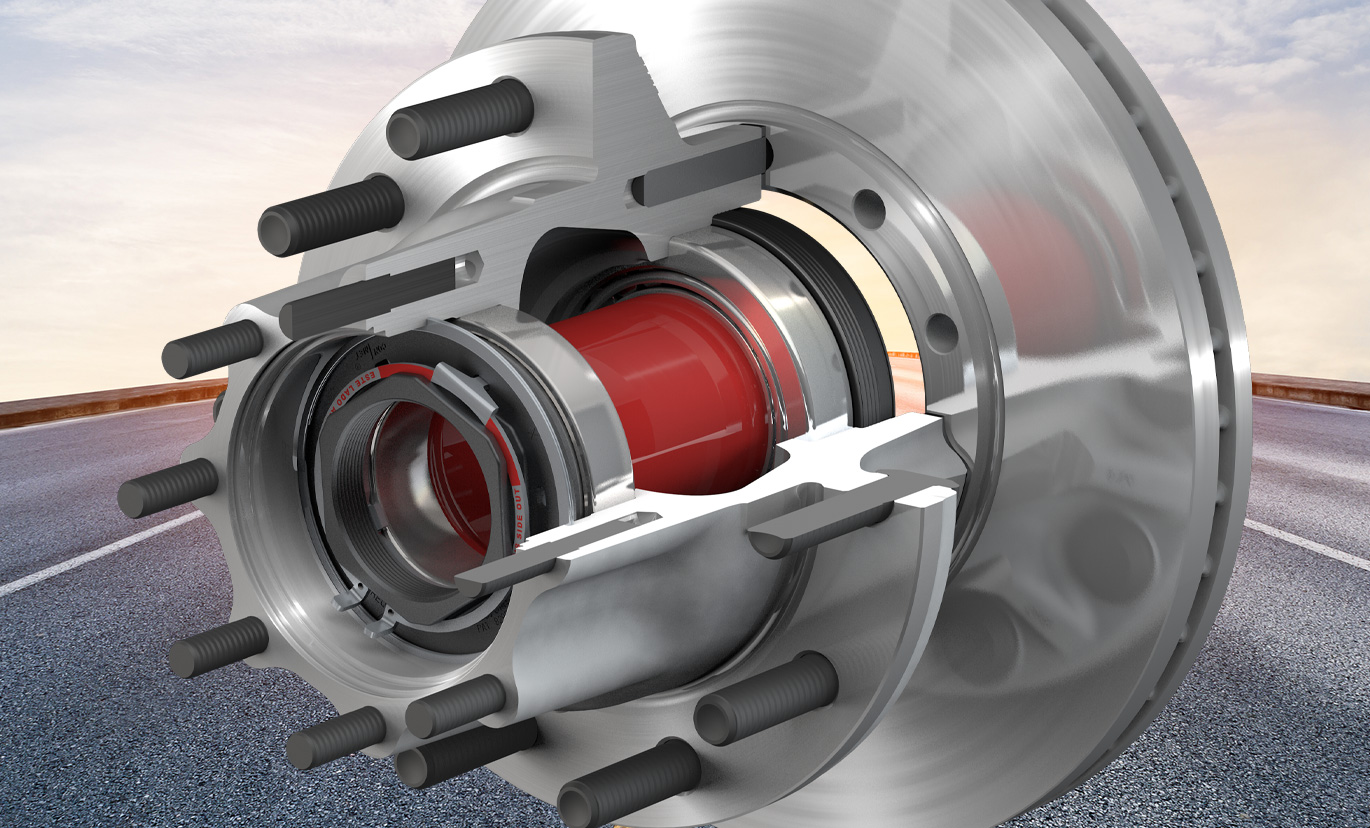

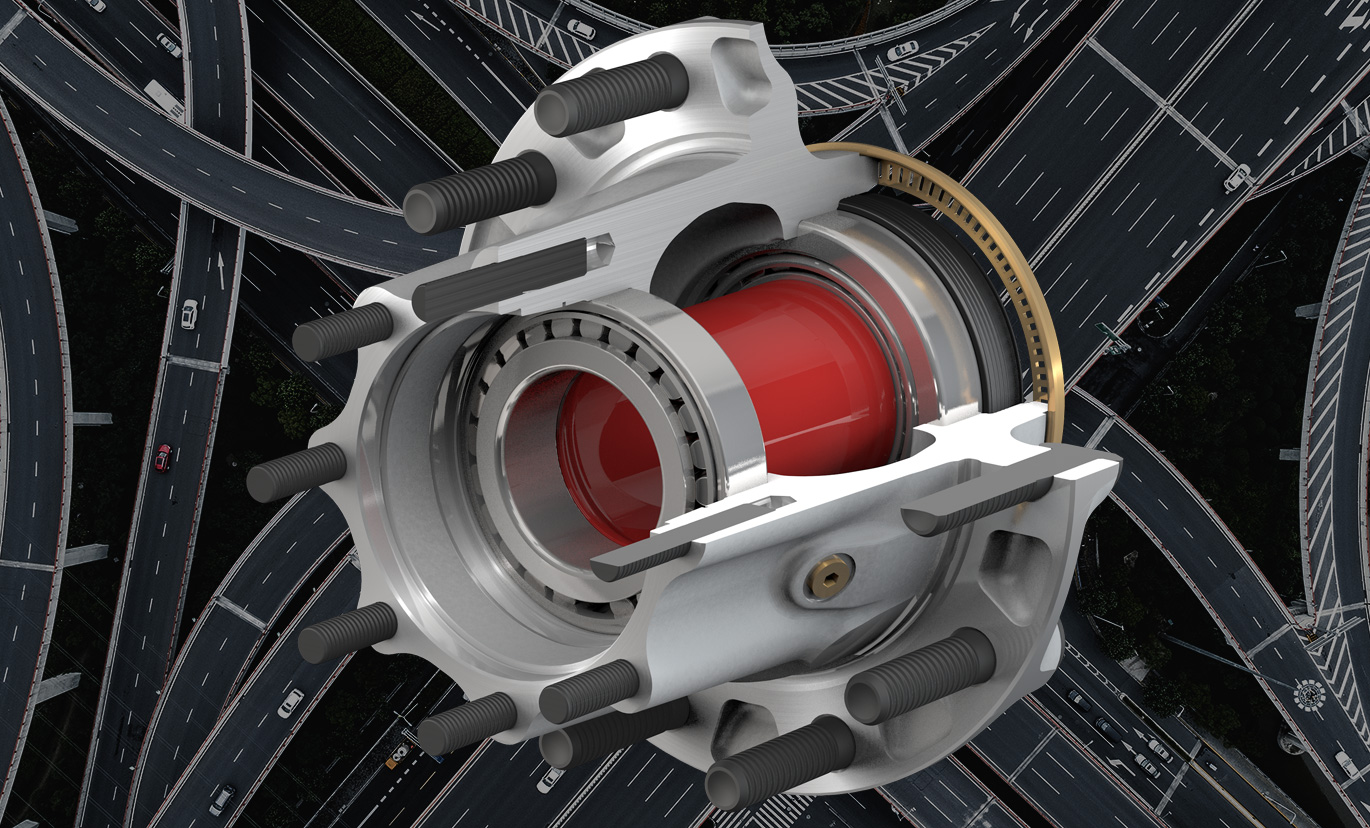

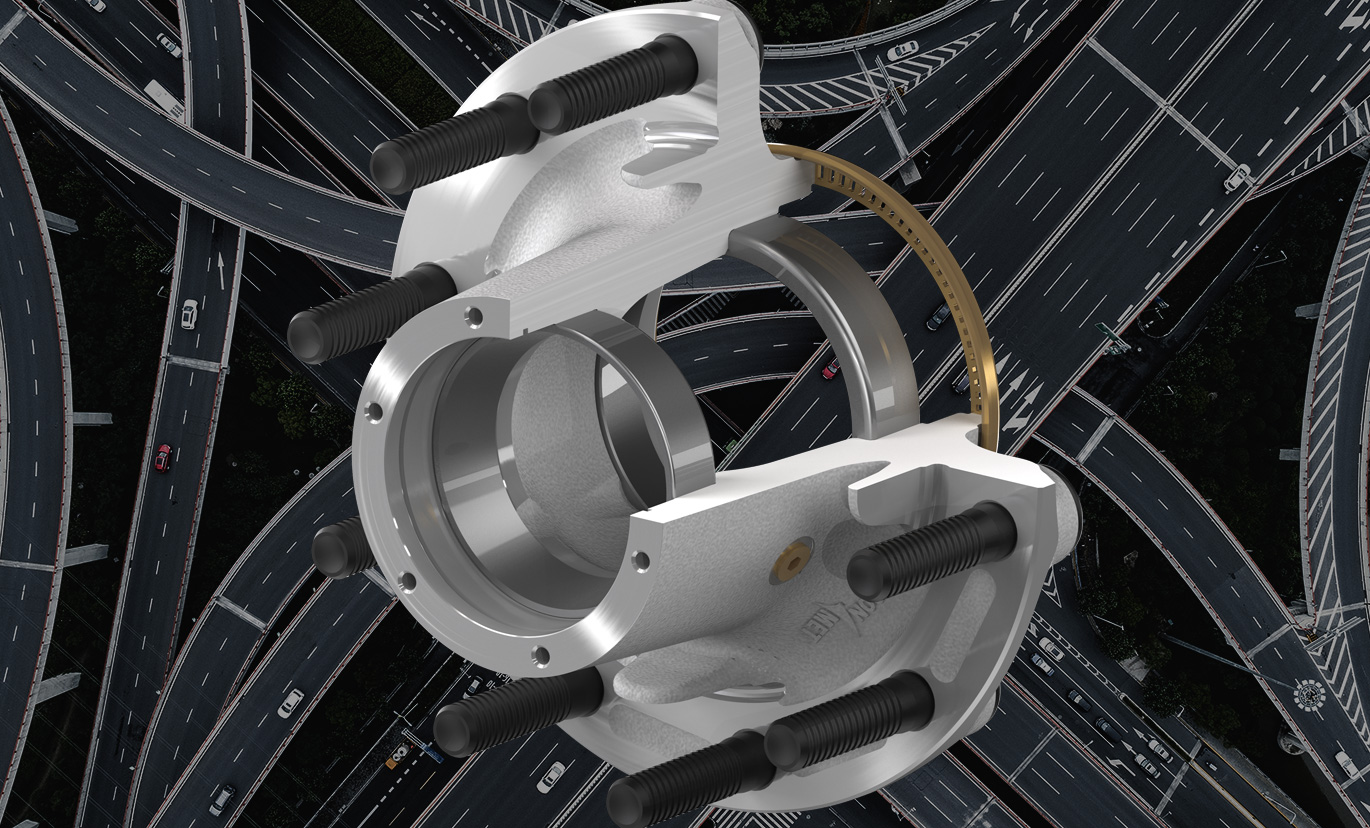

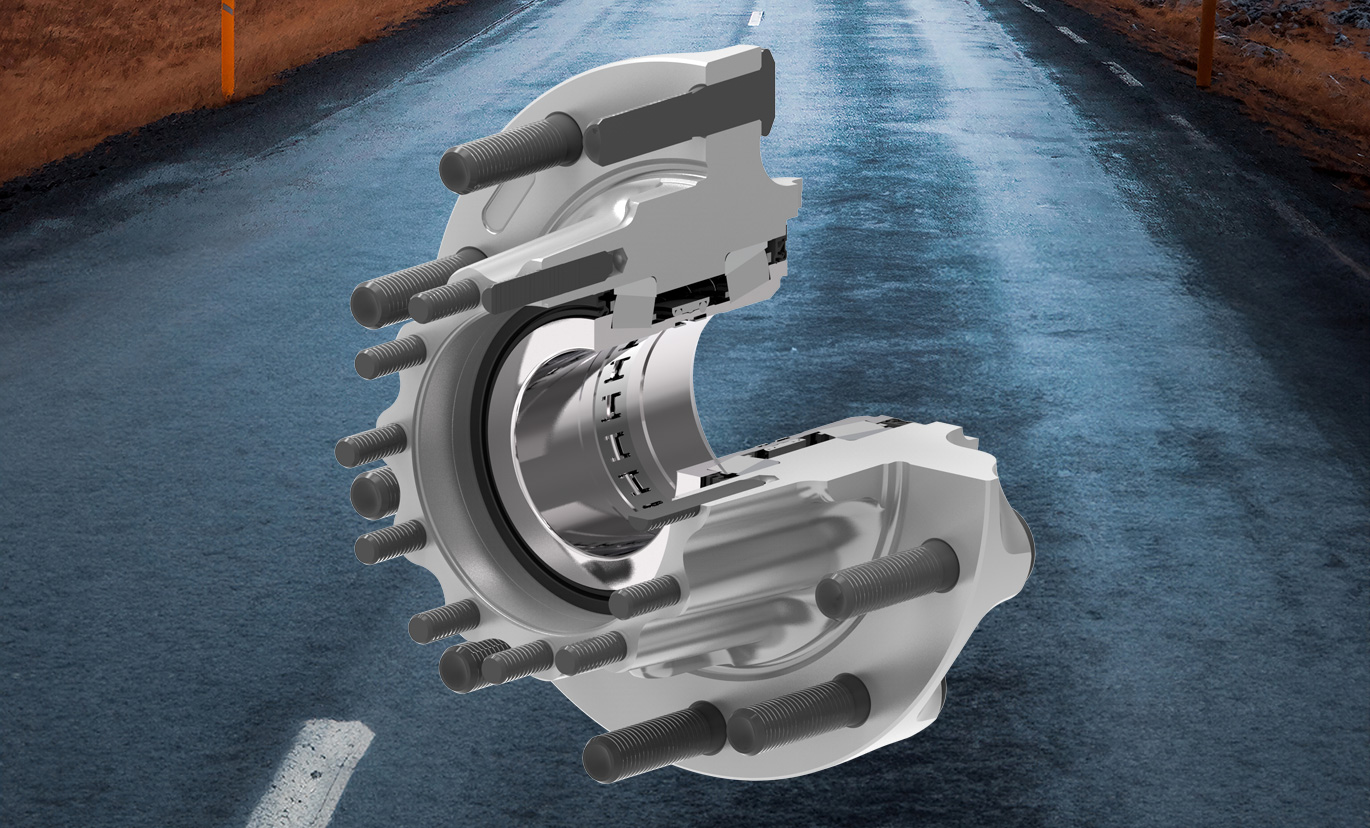

The complete ConMet proprietary wheel end including our revolutionary spindle nut.

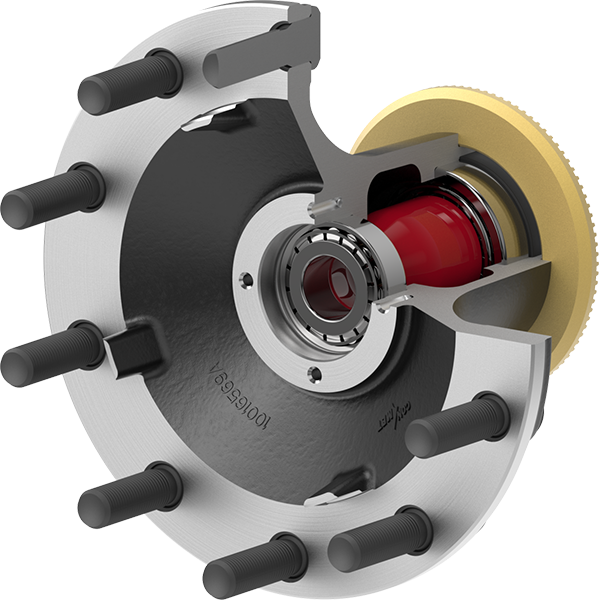

ConMet’s patented integrated nut system significantly improves wheel end clamp load, makes installation easier, aids in removal of the hub, and provides improved safety features.

A precision-machined spacer controls the spacing between our proprietary, tapered roller bearings, eliminating the need for manual adjustment. The design removes the guesswork from wheel end assembly with a precise, repeatable bearing setting.

ConMet premium wheel seals withstand harsh road conditions, poor weather, and frequent braking, playing a vital role in the extended performance of the wheel end.

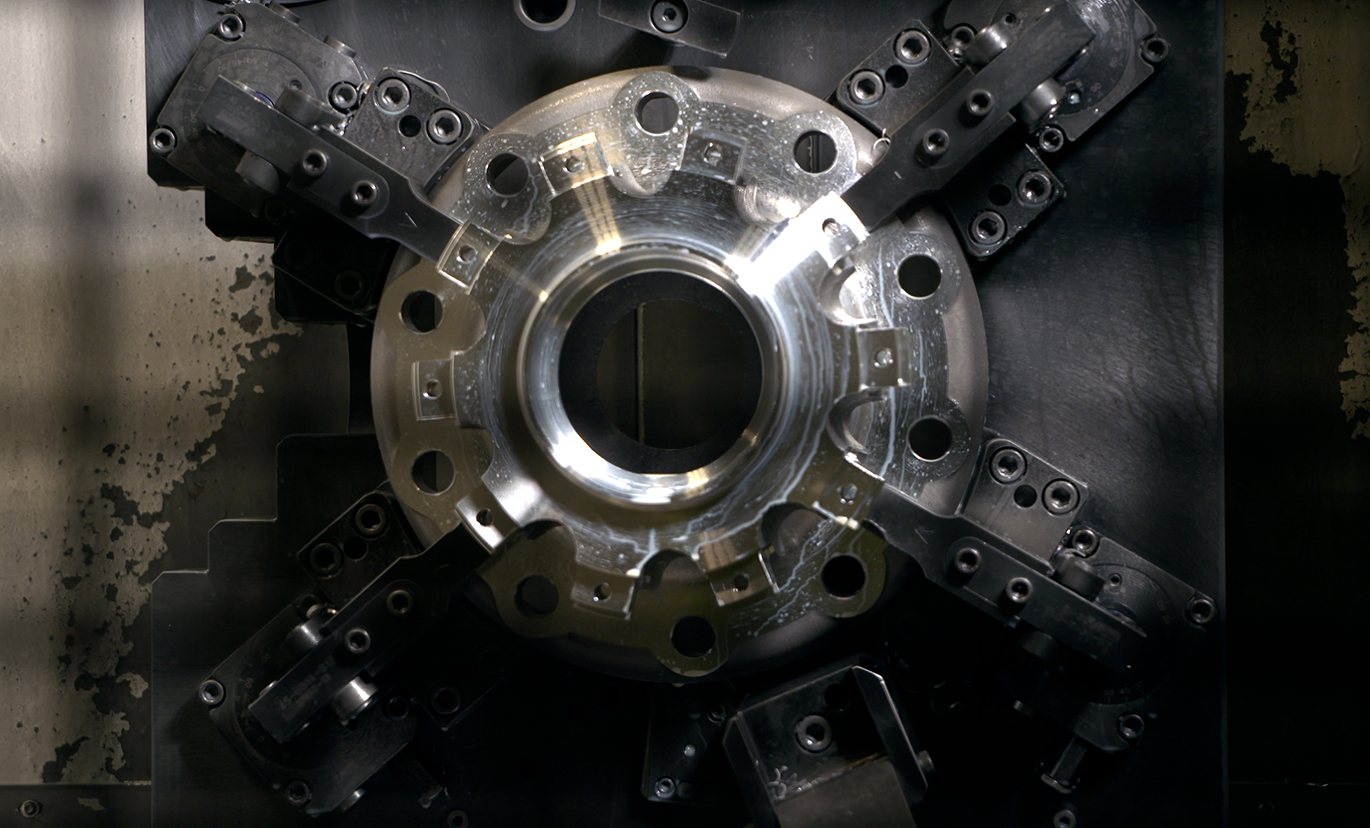

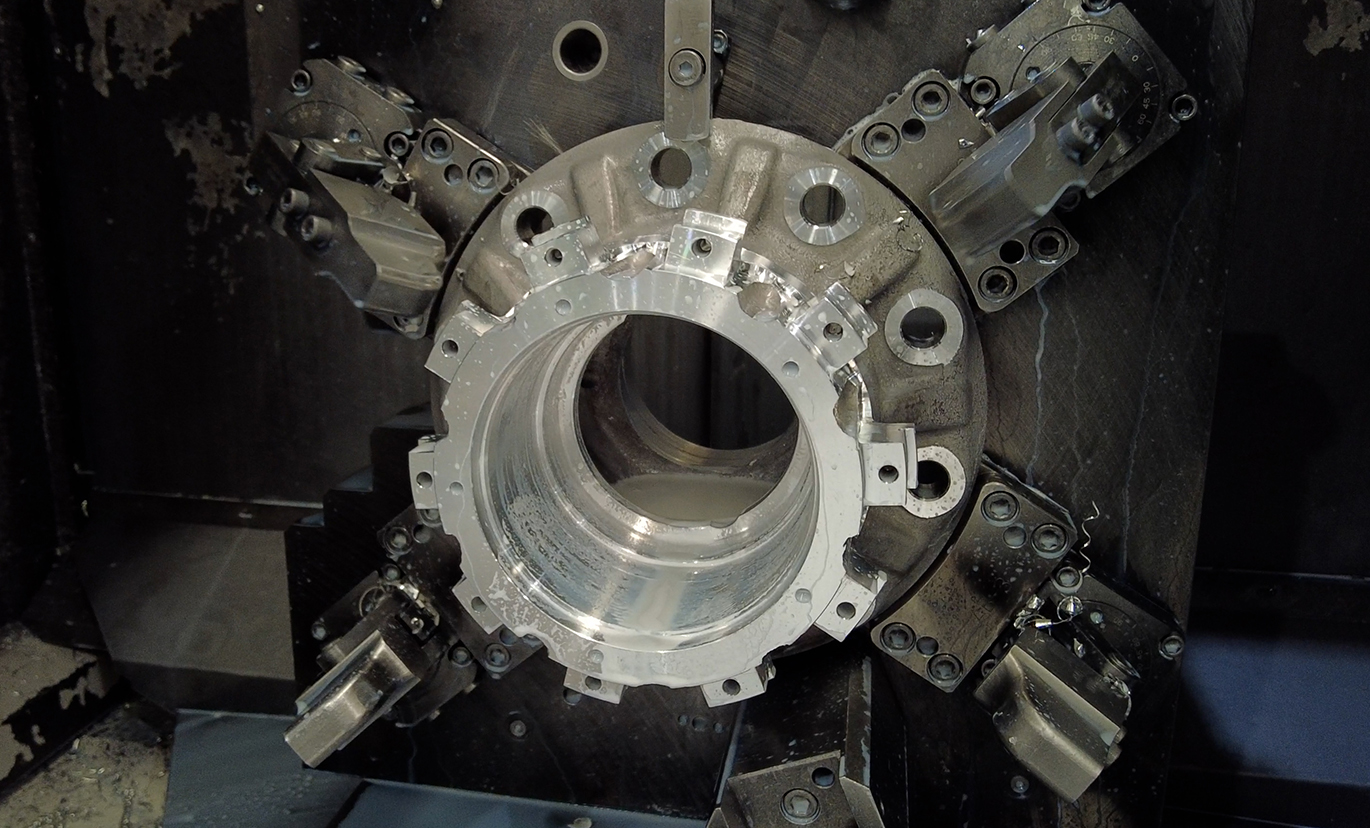

Precision machined aluminum or iron hub castings ensure high quality and tight tolerances across high volume production.

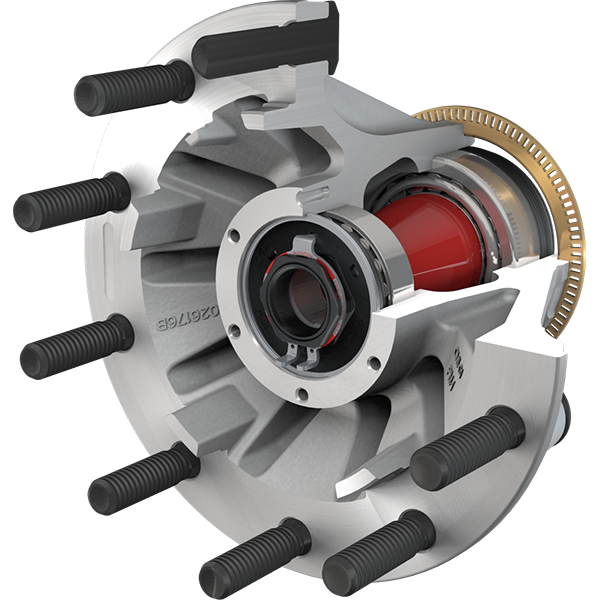

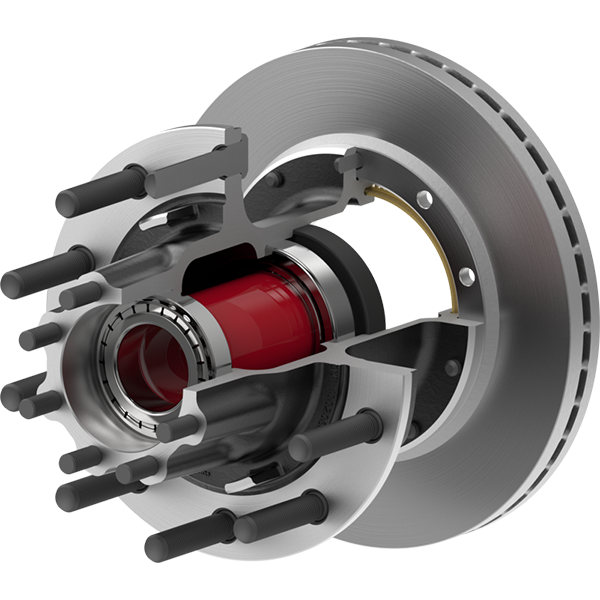

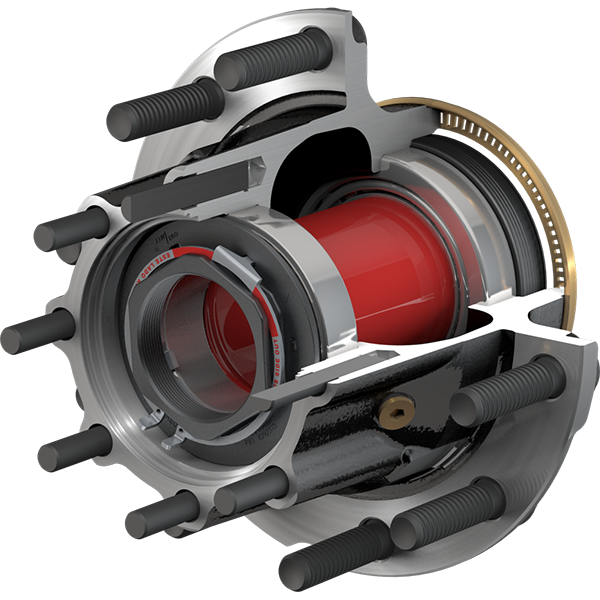

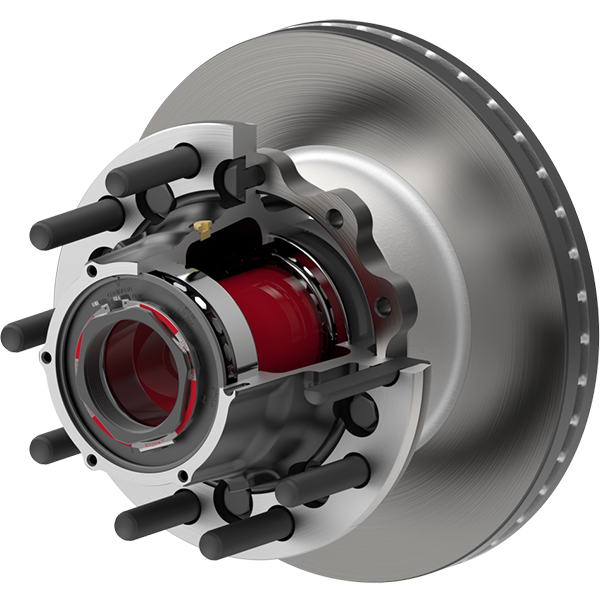

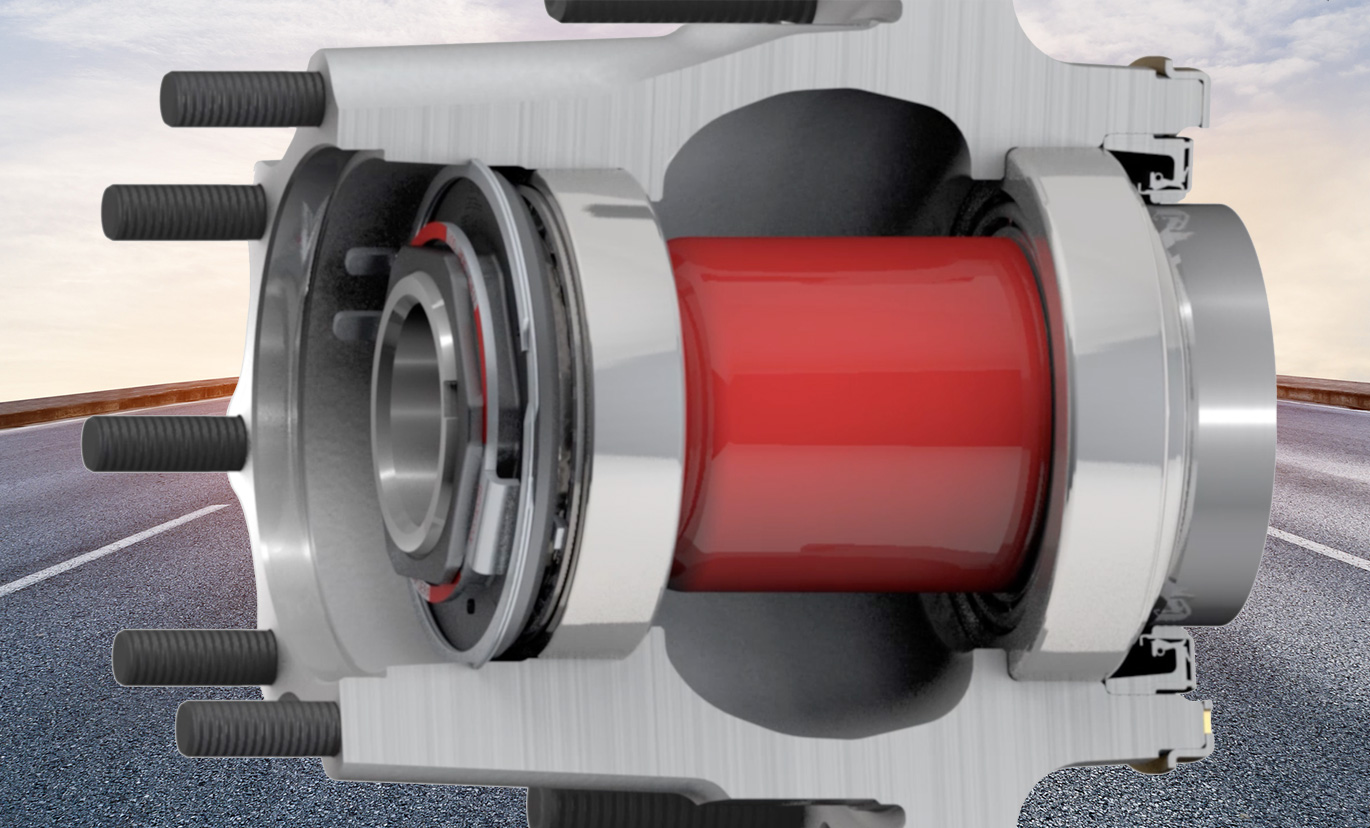

A precision-machined spacer controls the spacing between our tapered roller bearings, eliminating the need for manual adjustment. The design removes the guesswork from wheel end assembly with a precise, repeatable bearing setting.

ConMet premium wheel seals withstand harsh road conditions, poor weather, and frequent braking, playing a vital role in the overall protection of the hub.

Precision machined aluminum or iron hub castings ensure high quality and tight tolerances across high volume production.

Precision machined aluminum or iron hub castings ensure high quality and tight tolerances across high volume production.

Includes wheel studs and bearing cups installed.

Precision machined aluminum or iron hub castings ensure high quality and tight tolerances across high volume production.

A greased-for-life bearing system.

ConMet Hub Assemblies

The most complete product portfolio in the industry.

ConMet Wheel Hubs In Action

How ConMet’s partners and customers use our products.

Latest News

Newest development, recognition and success stories from ConMet.

Support

Unparalleled Customer Support

At ConMet, we’re your dedicated partner at every turn, offering comprehensive assistance from responsive customer service and hassle-free warranty claims to expert product support and in-depth service training.