Labor and material shortages across the globe have impacted life and industry throughout the supply chain, from manufacturers who are struggling to procure raw materials to the consumers who are unable to find the products they need.

Sometimes overlooked in the discussion is that the supply chain itself has its own material and labor needs. The availability of the goods themselves is just one part of the equation. Another is delivery, as we rely on trucks to haul our goods to retail and distribution outlets. To remain operational, the trucking industry has its own supply needs that need to be met. Shortages of drivers, maintenance technicians, and the delay of tractor and trailer builds are some of the setbacks facing the industry today.

With rising fuel costs and demand for freight delivery at a record high, fleets are searching for innovative and efficient ways to keep vehicles on the road. The lack of new builds means fleets are forced to keep older assets in service longer, which often increases maintenance and lends to a higher potential for roadside events. To combat these risks, fleets are ramping up preventative maintenance programs and retrofitting older equipment with new technology like telematics solutions to help increase visibility and operational efficiency.

One area in particular where fleets are focused on extending service life is transport refrigeration units (TRUs) because of their critical function hauling perishable goods such as groceries and pharmaceuticals. However, standard TRUs include an inefficient diesel engine and often require a lot of maintenance and fuel to keep them functional. To maximize uptime on existing assets, fleets should consider upfitting with an electric TRU (eTRU), which often requires less maintenance.

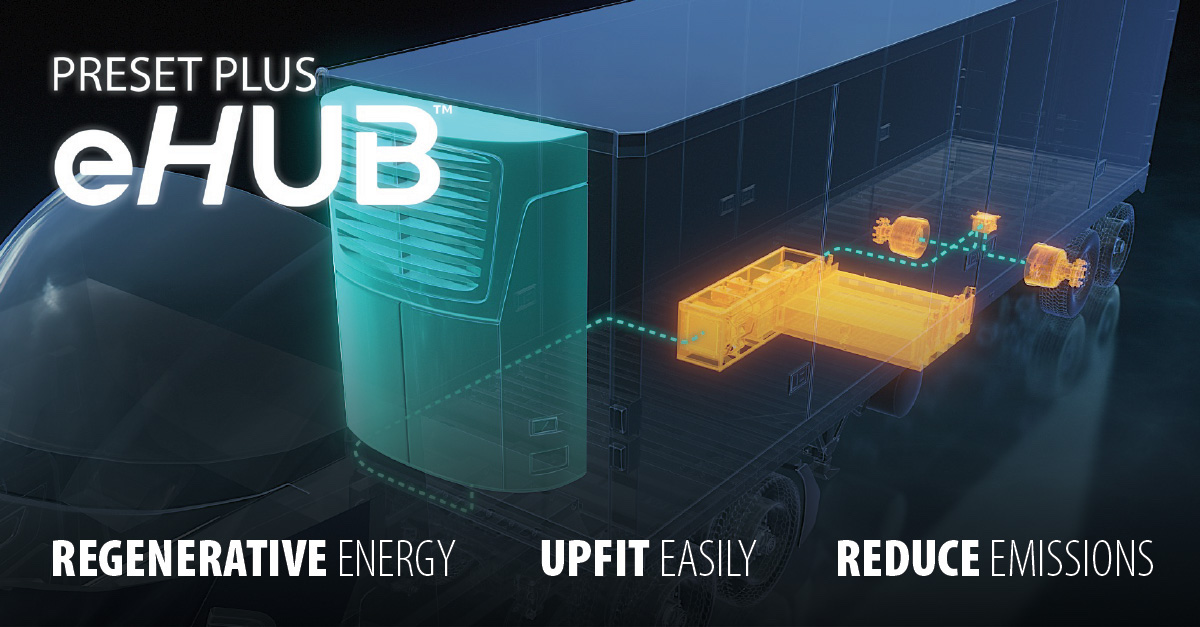

When deciding to upfit to an electrified reefer trailer, fleets have several options. Traditionally, to avoid the use of diesel, eTRUs have required access to shore power, large battery packs, electrified axles, or solar panels, all of which rely on existing infrastructure, add significant weight, or are limited to new builds. In-wheel motor electrification systems, like the Preset Plus eHub system, package an electric motor within the wheel end and are now available as an efficient, retrofittable alternative for fleets looking to go electric.

Electric reefer systems that utilize in-wheel motors to capture kinetic energy and repurpose it as electricity, are capable of storing excess energy in a high-capacity battery that can be shared with the TRU as needed. This unique energy harvesting method means power is captured on the road, with limited need for shore power or charging stations, making it suitable for a wide variety of fleets. This energy can also be used to power the motors and provide decentralized vehicle propulsion, taking load off the tractor and smoothing overall vehicle acceleration.

The flexible mechanical design of in-wheel electrification systems makes them an easy retrofittable solution. Modular components fit any trailer configuration, including those with modifications such as lift gates and ramps while variable battery pack size and custom controls optimize energy use and limit net weight add. There’s no need for fleets to purchase a new TRU either—in-wheel systems can accommodate existing electric standby TRUs. All these features combined allow for customization to meet the needs of every fleet, including the energy needs for specific routes and delivery schedules.

Additionally, in-wheel motors capture energy that is often created in braking events. This means less wear on friction brakes, helping to reduce brake maintenance needs and increase uptime. Eliminating the need for the diesel engine inside the TRU, also simplifies maintenance as well as decreasing fuel costs, allowing fleets to maximize the value and operational efficiency of every trailer.

While supply chain uncertainties continue to loom, upfitting reefer trailers with electric in-wheel motor systems like the eHub system from ConMet has potential to extend the utilization of aging reefer assets. Additionally, fleets can turn to ConMet for new and exciting technologies that will increase operational efficiencies and propel the industry further for years to come.

More info: ConMet eMobility

VANCOUVER, WA | by Beto Dantas, Chief Technology and Innovations Officer