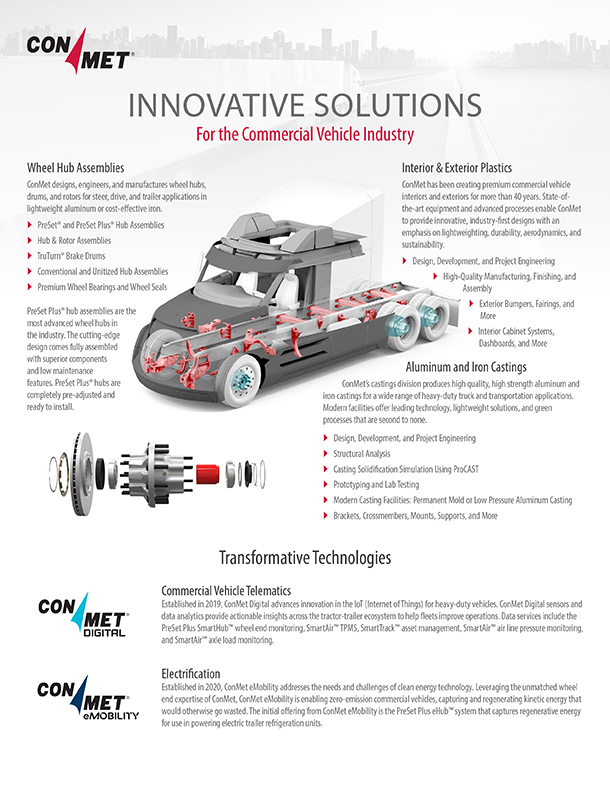

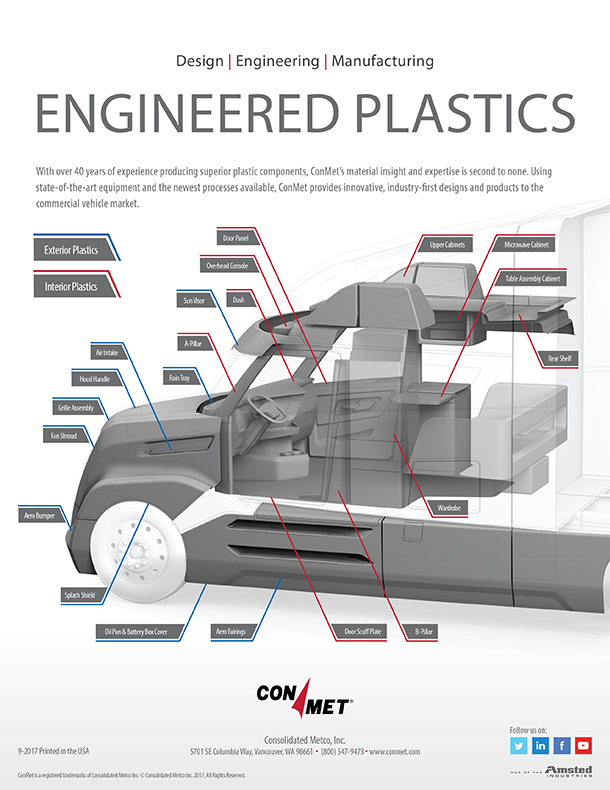

Interior & exterior plastic systems

Best-in-Class: Design, development, manufacturing, and technology

Full-Service Solutions Provider

Delivering the best components in the commercial vehicle industry for the last 40 years

A full-service collaborative approach

From concept to creation, our team of engineers and plastics experts partner with our customers to design, develop, test, and manufacture solutions tailored to their needs and specifications.

Designing and delivering our customers’ vision

Our design, engineering, and manufacturing processes enable us to create tailored solutions to meet our customers most precise requirements.

Relentless evaluation and application of new technologies

Research and implementation of new innovations and applications in plastics that will deliver maximum value and competitive advantage to our customers

Advanced Plastics

Our unique approach to plastic component design and manufacturing ensures high quality results.

Delivering product styling, concept ideation, design, testing, program management, and advance manufacturing tooling through to final production, our expertise in full-service engineering is core to our success as a valued OEM partner.

Simplifying high complexity assembly with line sequencing, large injection molding capability, innovative molding technology, and prime and top coat painting expertise enable ConMet to deliver the most challenging OEM projects with best in class quality metrics.

We continuously challenge ourselves on finding innovative solutions to reduce cost and weight, improve aerodynamics, and implement sustainable materials through consistent improvement and exploration of new technology for our customers.

We strive to maximize our manufacturing footprint with the strategic locality of our main plants to truck plants and satellite facilities right next door. Complementing our full engineering services, our new ConMet Technical Center is located right next to our Corporate Engineering site.

Solutions in Action

Serving award-winning solutions in partnership with strategic suppliers

Support

Unparalleled Customer Support

At ConMet, we’re your dedicated partner at every turn, offering comprehensive assistance from responsive customer service and hassle-free warranty claims to expert product support and in-depth service training.