In recent years, many North American truck and trailer original equipment manufacturers (OEMs) have recognized the benefits of air disc brakes (ADB) and have made them standard fit on several models. As Fleet Equipment outlines, disc brakes offer significant safety and performance advantages such as shortened stopping distances and limited brake fade. These advantages are amplified when coupled with enhanced braking systems (EBS) and can lead to a decrease in accidents and fewer compliance, safety, and accountability (CSA) violations. ADB also offers a significant drop in the total cost of ownership through reduced maintenance costs, extended brake pad life, and lessened susceptibility to road and water effects.

The National Highway Traffic Safety Administration (NHTSA) filed a ruling in 2009 mandating a 30 percent reduction in minimum stopping distances for commercial vehicles. Prior to this ruling, ADB adoption had been initially slow, but with a 2013 compliance date for the vast majority of heavy-duty trucks, the industry’s need for superior braking performance began to overshadow the slightly higher upfront cost and assembly weight of disc brakes.

Although drums still dominate the industry, disc brakes are garnering a sizeable portion of the market as OEMs begin to opt for ADB and suppliers work to further improve assembly design and serviceability. “Air disc brakes are becoming increasingly popular and will likely become the most popular brake option within the next three to five years,” ConMet’s Vice President of Engineering, Bryan Williams, told Trucking Info. Williams continued, “most fleets will find over time that disc brakes are a better option than drum brakes due to their performance and maintenance advantages”.

These advantages, combined with safety and regulatory benefits, continue to incentivize the adoption of ADB. Cost has been the primary barrier to adoption, but that limitation is beginning to weaken as suppliers work to improve ADB assemblies by making them lighter, more cost effective, and simpler in design. The article explains that by the end of 2018, ADB accounted for about 25 percent of the truck market and that figure is expected to double by 2021. Similarly, around 20 percent of trailers were fitted with ADB, a proportion that will likely increase around 2 to 5 percent each year.

Market attention is expected to continue as electronic brake controls becomes more advanced and the industry continues to make significant progress toward complete vehicle connectivity and autonomy. “The onboard computing systems that are critical for integrating braking and safety systems on trucks work on precise controls that demand very consistent and repeatable braking performance”, an advantage that clearly belongs to disc brakes, the article details. When considering drum over disc brakes, it seems ADB is simply better suited to meet the ever-evolving needs of a dynamic industry.

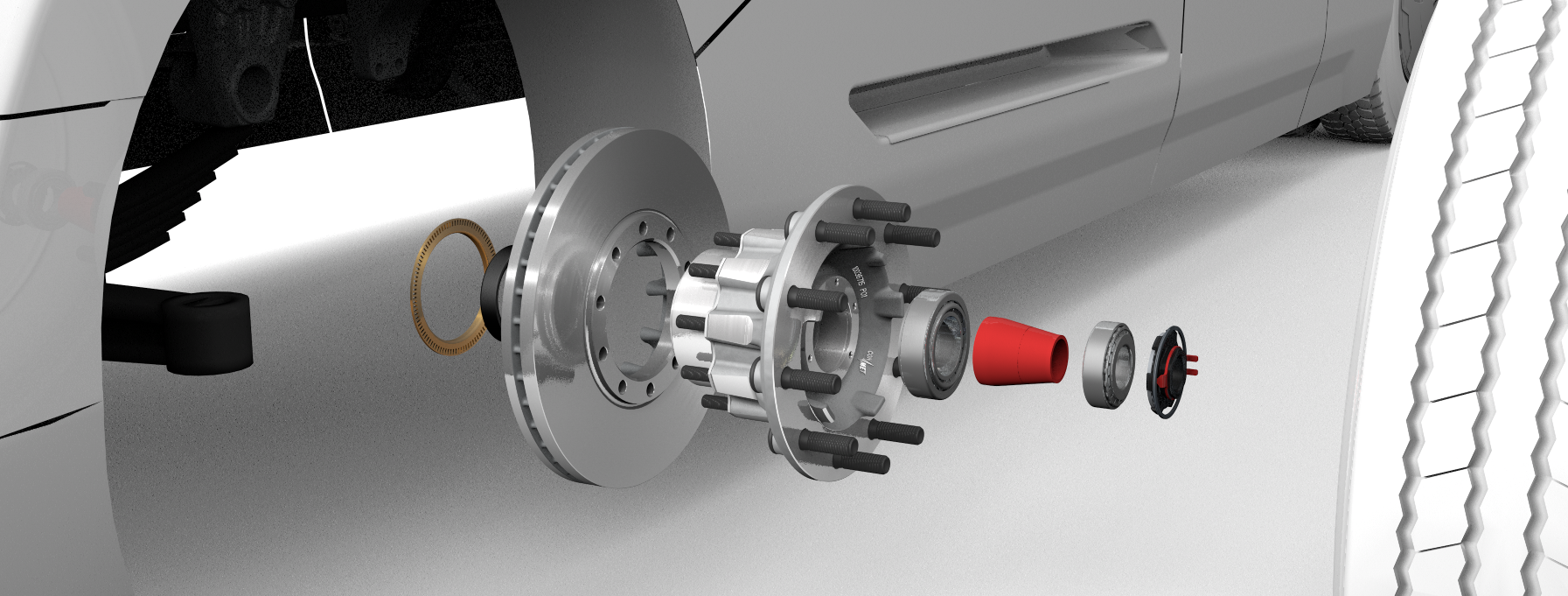

ConMet is committed to advancing air disc brake technology and developing innovative solutions to help fleets improve safety, increase uptime, and reduce maintenance costs. Standard fit at several North American OEMs, ConMet hub and rotor assemblies are an industry trusted, lightweight, and durable ADB solution. To learn more about the advantages of ADB and ConMet’s premium, high-performance hub and rotor assemblies, click here. For more information on what ConMet’s doing to advance the industry and details on current innovation projects, click here.